The corn stover should be stored under the conditions of keeping its normal amount of moisture against rain and soaking from the ground, avoiding decay and ensuring protection against fire. The selection of a storage type will depend on location and local conditions. The corn stover can be stored in open storage, tarped storage, permanent structure storage or anaerobic storage[1]. Several factors should be considered when selecting appropriate storage systems: feedstock stability during storage, cost of storage infrastructure, accessibility of feedstock during the entire storage duration, integration of storage platform with processing plant.

The storage of biomass in permanent structures offers many advantages in comparison with other systems. However, due to relatively low density of corn stover, including bales, and high capital costs for new storages building the permanent storages are economically unfeasible. In the case, if stakeholder has permanent storages he can use them for corn stover.

Open-air storage (Fig. 1, 2) can be used for temporary local storages of corn stover when the upper layer of biomass serving as coverage. Also, it may be used for main storage facility in some regions, but it is necessary to do this very carefully due to dry matter losses in the biomass.

Fig. 1 Photo of open storage of by-products of corn for energy needs of Nufri company, Mollerussa city, Spain [5]

Anaerobic storage or ensiling is a very common storage method for wet feedstocks in the livestock industry. Anaerobic storage remains economically viable for high moisture feedstocks, particularly for early season bale storage or for emergency storage during extremely wet harvest seasons.

The tarped storage of corn stover offers the optimal balance of cost and quality preservation. Agrofibre material can be used as tarp material, which provides rain and snow protection. It gives a possibility of air out on the surface, which prevents the formation of fungus and mold. The agrofibre is used for wood chips drying. The period of agrofibre usage is more than 5 years[2]. The corn stover tarped storage with agrofibre was chosen for further cost assessment.

Fig. 2 Photo of open storage of by-products of corn for energy needs of Nufri company, Mollerussa city, Spain [5]

The corn stover storage facilities have to be arranged according to the Fire Safety Regulations in Agricultural Sector of Ukraine (Order of Ministry of agriculture and Ministry of emergency situation #730/770)[3]. The area of one stack of straw bales must be less than 500 m2 and shredded straw must be less than 300 m2. It is allowed to dispose of bales (shredded straw) in double stacks with distance not less than 6 m between stacks in pair and not less than 30 m between adjacent double stacks.

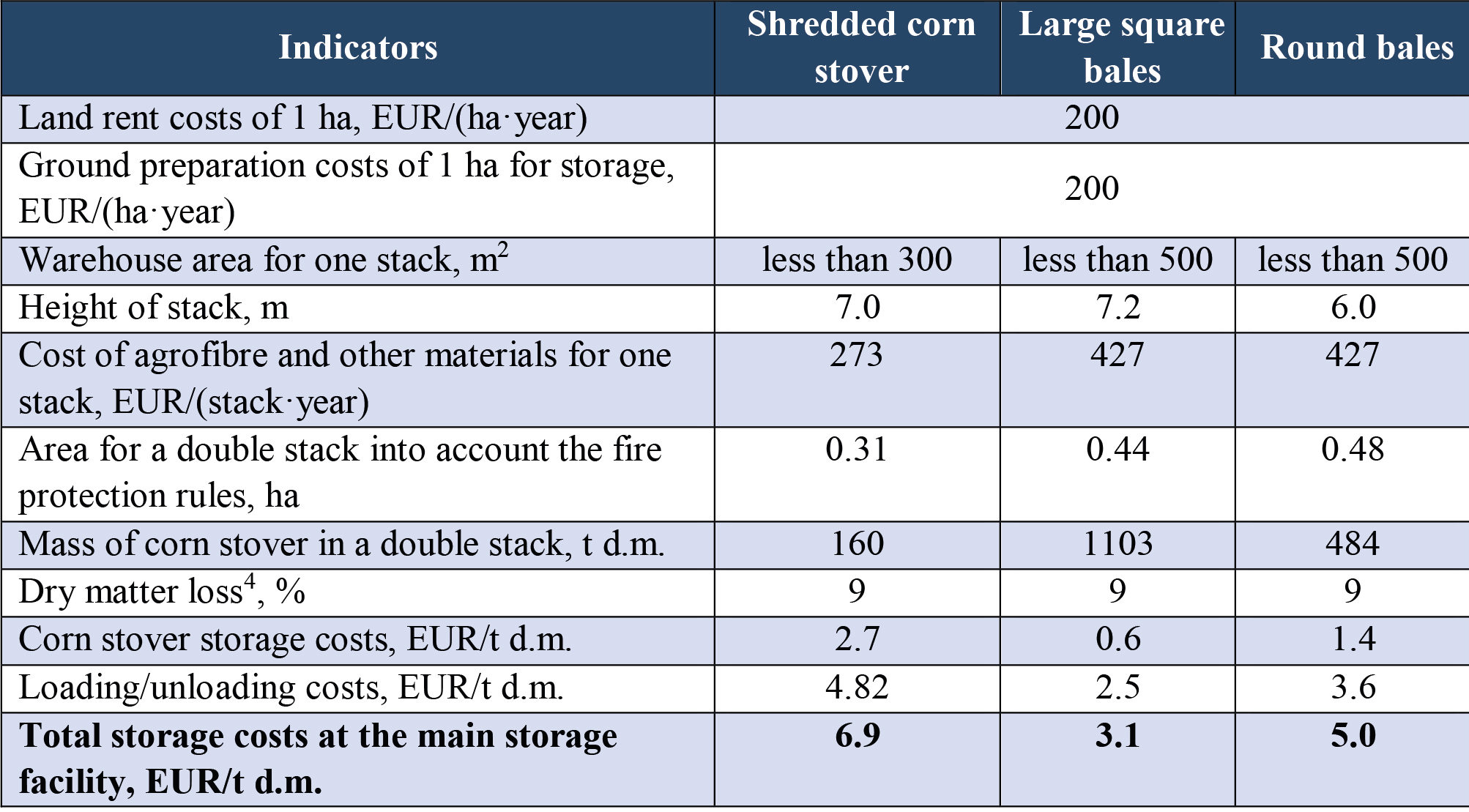

It is important to secure free access to biomass for the loaders. The main cost elements of corn stover tarped storage are land rent costs, ground preparation costs, tarped material, loading/unloading costs, guard costs and costs associated with feedstock losses through dry matter loss. The costs assessment of tarped storage for shredded, large square bales and round bales of corn stover is given in Table 2.9. The guard costs aren’t taken into account, due to assumption, that the main corn stover storage facility will be placed near the farmer`s storage facility with existing guard system.

Table 2.9. Corn stover storage costs at the main storage facility.

The large square bales tarped storage costs are 3.1 EUR/ t d.m., which are lower than storage costs of round bales (5.0 EUR/t d.m.) and shredded corn stover (6.9 EUR/t d.m.).

Author: Semen Drahniev

[1] https://store.extension.iastate.edu/product/14077

[2] http://zavod-kobzarenko.derevo.ua/catalog/details/6019

[3] http://zakon.rada.gov.ua/laws/show/z0313-07

[4] https://store.extension.iastate.edu/product/14078

[5] In photos, added to this article, the open storage of by-products of corn in Mollerussa city, Spain is shown. The bales are co-burned with wood from pruning local gardens. As a result the heat and electricity (CHP: 10 MW heat + 2 MW el. and 10 MW boiler) are produced for Nufri’s company industrial needs. The company annually processes 600,000 tonnes of fruit and produces 170,000 tonnes of canned food.

Read also:

State of the art of corn production in the world and in Ukraine

Сorn residues and harvesting in Ukraine

Potential of corn residues in Ukraine in 2018

Fuel characteristics and properties of corn residues

Technologies for harvesting corn and corn residues

Corn harvesting technologies: in rolls and crushed form

Cost of equipment and operations related to harvesting of corn residues