Biomass briquettes are pressed materials of cylindrical, rectangular or any other shape with cross dimension that is not less than 25 mm and with the length of 100-400 mm. The typical diameter of a briquette is 60-75 mm, and its length usually is within five diameters. There are no standard sizes for this product (Fig. 1).

|

а) NESTRO (NIELSEN) |

b) RUF | c) Pini&Kay |

Fig. 1 General view of biomass briquettes

Briquettes may be of very different shapes but on the whole three types can be distinguished: NESTRO, RUF, and Pini&Kay (the names are based on the names of companies which manufacture well-known presses for the production of briquettes of this type)[1]:

- NESTRO (NIELSEN) is long briquettes of cylindrical or multiangular cross-section mainly without the inner hole (Fig. 1а). NESTRO briquettes are manufactured with hydraulic presses and NIELSEN briquettes with mechanical presses at the expense of high pressure. These briquettes are of unlimited length and can be cut into both “disks” and “logs”. A buyer orders the shape of the briquette. The production process is rather simple so highly qualified personnel is not required. Advantages of NESTRO (NIELSEN) briquettes are rather low production cost and quite high density (1.0-1.15 t/m3). Disadvantage is poor moisture resistance of the briquettes (therefore, the secure package is required).

- RUF is briquettes of a brick shape (Fig. 1b) produced with hydraulic presses at the expense of high pressure. Dimensions of the briquette depend on the feedstock looseness and applied pressure. Hydraulic presses are considered the most reliable briquetting equipment but they are rather expensive. Features of the production process are minimal requirements to the operating personnel and to manufacturing organization. Advantage of RUF briquettes is a low production cost. Disadvantages are the lowest density compared with other types of briquettes (0.75-0.80 t/m3); poor moisture resistance of the briquettes (therefore secure package is required); poor mechanical resistance that has a negative impact upon the briquette state after a long transportation.

- Pini&Kay is briquettes of the cylindrical or multiangular cross-section with the inner through hole (Fig. 1c). The hole ensures better air movement during combustion. Pini&Kay briquettes are manufactured by extrusion with mechanical (screw) presses by mixing of high pressure and thermal processing (roasting). The high pressing temperature (250-350 ºС) causes burning-off and strengthening of briquettes surface that ensures transportation of briquettes without damage. Features of the production process are strict requirements to feedstock moisture content (< 8%) and feedstock comminution, high energy-intensity need in highly qualified personnel. Advantages of briquettes of this type are high mechanical resistance and moisture resistance, and the highest density compared with briquettes of other types (1.1-1.4 t/m3). A disadvantage is a high production cost.

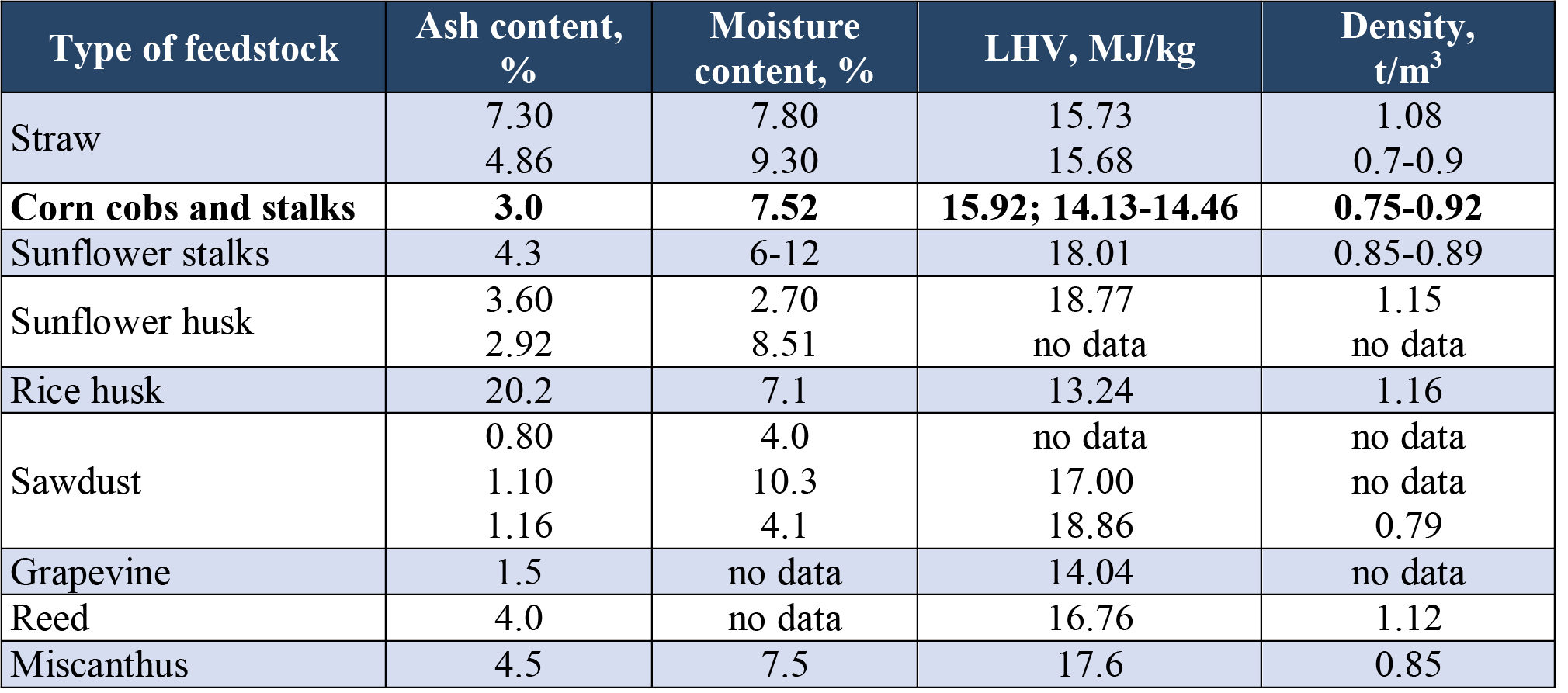

Density is one of the most important indexes of quality of biomass briquettes. Usually, it is 0.8-1.3 t/m3 at the moisture content of the pressed biomass of 8-14%. Density is the main factor that determines mechanical strength and water resistance of a briquette. The heating value of a briquette depends on the type of feedstock used and on the moisture content. A typical range of the lower heating value of biomass briquettes is 16-18 MJ/kg (Table 1).

Table 1. Characteristics of briquettes produced from different types of biomass[2] [3] [4] [5] [6] [7] [8] [9] [10].

An important advantage of briquettes as fuel is the constancy of temperature during combustion for several hours. Biomass briquettes can be combusted in domestic boilers and small boilers for solid fuels with manual loading (up to ~100-150 kW), which often are already available in households, state-financed institutions or institutions of the social sphere. In the market, there are also automated boilers with a bunker (up to ~240 kW) designed for biomass briquettes. Briquettes of lower density (that is «softer» due to pressing of wetter feedstock) can be used in large boilers with screw feeding. It is expected that the screw manufactured of strong metal will be able to crush briquettes and ensure their uninterrupted feeding into the furnace.

Author: Semen Drahniev, Tetiana Zhelyezna

[1] UABio Position Paper N 20 “Analysis of possibilities for the production and use of agribiomass briquettes in Ukraine” (2018) http://uabio.org/img/files/docs/position-paper-uabio-20-en.pdf

[2] http://term.od.ua/blog/toplivnie-brikety-drevesnie/ (experimental data)

[3] Bio-briquettes based on straw http://www.gns-halle.de/downloads/info_straw_briquettes.pdf

[4] Józef Kowalczuk, Janusz Zarajczyk, Paweł Sobczak et al. The usefulness of briquettes and pellets from selected plant materials for energy purposes. TEKA. COMMISSION OF MOTORIZATION AND ENERGETICS IN AGRICULTURE – 2012, Vol. 12, No. 2, 311–313.

[5]https://bioresources.cnr.ncsu.edu/BioRes_10/BioRes_10_3_5515_Gong_LWTW_Compress_Charact_Energy_Require_Briquettes_7255.pdf

[6] https://bioekoprom.com.ua/ua/novini/teplotvornaya_sposobnost_toplivnyih_briketov_i_nekotoryih_vidov_topliva/

[7] D.P. Kindzera, V.М. Atamaniuk, R.R. Gosovskyi, І.М. Motil. Study of formation of briquettes from vegetable feedstock and determination of their characteristics. Scientific Bulletin of the National Forestry Engineering University of Ukraine, 2013, issue 23.17, p. 138-146 http://nltu.edu.ua/nv/Archive/2013/23_17/138_Kin.pdf

[8] http://bio.ukrbio.com/ru/articles/4355/

[9] O. Urbanovicova, K. Kristof, P. Findura et al. Physical and mechanical properties of briquettes produced from energy plants. Acta Universitatis Agriculturae et Silviculturae Mendelianae Brunensis, V. 65, 2017, p. 219-224 https://acta.mendelu.cz/media/pdf/actaun_2017065010219.pdf

[10] http://www.biofuelmachines.com/miscanthus-pellet-mill-and-miscanthus-pellet-study.html

Read also:

State of the art of corn production in the world and in Ukraine

Сorn residues and harvesting in Ukraine

Potential of corn residues in Ukraine in 2018

Fuel characteristics and properties of corn residues

Technologies for harvesting corn and corn residues

Corn harvesting technologies: in rolls and crushed form

Cost of equipment and operations related to harvesting of corn residues

Corn residues storage costs