Biogas plants are traditionally associated primarily with energy companies that produce biogas for the production of electricity and heat. Therefore, the economic activity of biogas plants is focused on obtaining income from the sale of energy, which is directly related to the tariff per 1 kWh of energy produced from biogas. At the same time, monetized environmental and agro-technical effects, and sometimes direct income from the sale of digestate products, are also considered as potential sources of additional income.

Environmental effects include cost reductions for existing environmental payments / fines. Until 2012, this effect could be obtained from the sale of GHG emission reduction units under the Kyoto Protocol. In the future, the effect can be achieved by reducing CO2 tax payments.

Agro-technical effect can be calculated as cost savings for the purchase of mineral fertilizers or through additional income from increasing crop yields when applying digestate to soils. Recently, more and more attention has been paid to the economic evaluation of digestate as a fertilizer in Ukraine, especially in terms of permanent deterioration of arable land.

The economic efficiency of production and use of digestate products is determined by 2 main factors, namely:

- total content in 1 ton, availability for plants and market value of individual components in the product (organic carbon, NPK complex, other macro-and micronutrients, individual organic compounds);

- reduced costs for production, storage, transportation and application of 1 ton of product to the soil.

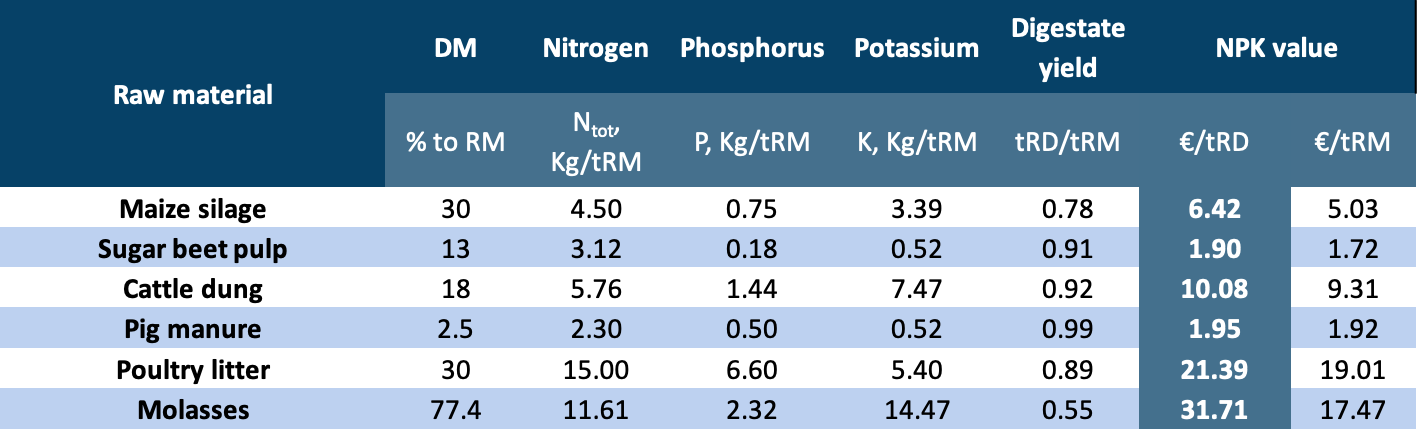

The market value of digestate products is usually estimated at the equivalent market value of nutrient analogues (N, P and K) in mineral fertilizers. An example of estimating the market value of digestate from the main types of raw materials used for biogas production is given in table 1.

Table 1 – NPK value estimation for basic raw materials

Notes: RM – raw material; RD – raw digestate. Based on price for N, P, K 0.75, 1.53, 0.68 €/Kg respectively. N-availability 60% in 1-st year of application is assumed in the calculation of NPK value of digestate.

As a rule, biogas plants use a mixture of different types of raw materials. For example, when mixing pig manure and corn silage in a mass ratio of 4:1, the equivalent market value of the formed “raw” digestate may be 3.3 €/t, and separated into liquid and solid fractions – 2.3 €/t and 17.1 €/t, respectively. Depending on the composition of the mixture, the equivalent NPK market value of the digestate can vary mainly in the range from 2 to 8 €/t.

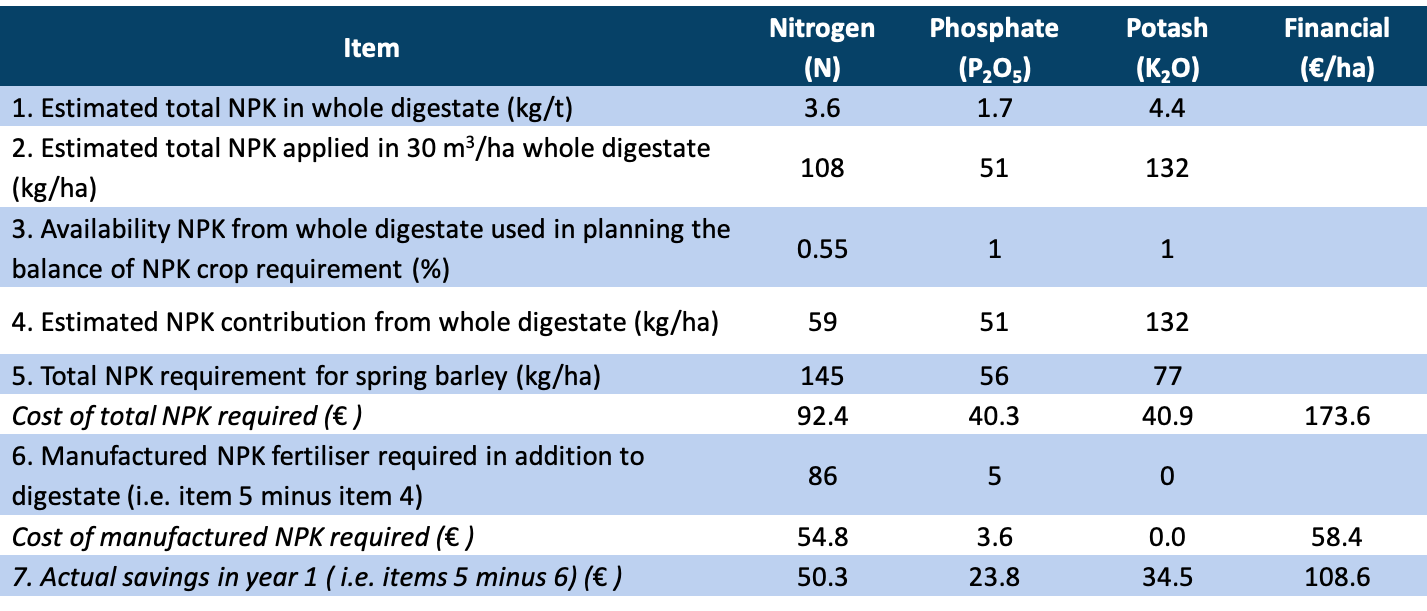

An example of estimating the actual agrotechnical effect of the application of digestate per 1 ha of cultivated arable land under spring barley is shown in table 2.

Table 2 – Savings in fertilizer costs where 30 m3/ha farm-based whole digestate was applied in spring prior to growing a spring barley crop [1]

Based on prices for N, phosphate and potash of 0.64, 0.72 and 0.53 €/kg respectively (the Farm Management Handbook. 2017/2018)

According to the results shown in table 2, it is possible to estimate digestate market value directly. Thus, since the application of 30 m3 of digestate per 1 ha allowed to save 109.57 €/ha on the purchase of mineral fertilizers, the equivalent market value of such digestate is 3.65 €/t.

These estimates show only the equivalent gross NPK value of the digestate. The actual economic effect of the use of the digestate will take into account the costs incurred for processing, transportation and application to the soil. Transportation and application costs arise in any case when using the digestate as a fertilizer, and depend on the distance of delivery and the application technique. Transportation of liquid digestate for every 10 km can reduce the value of digestate by 1 €/t, solid fraction – by 2.7 €/t. Thus, at significant distances of digestate transportation, its equivalent gross NPK value can be completely reduced by delivery costs.

The feasibility of the digestate processing using different technologies arises under certain conditions, and therefore is specific to each specific biogas project. The results of a study conducted by KTBL [2] showed that any further processing of “raw” digestate, regardless of the type of derivatives thereof, leads to a decrease in the equivalent net value of digestate by NPK complex, and therefore for most biogas plants simple land application of digestate is more economically attractive than digestate processing. However, if it is necessary to deliver the digestate products over long distances (more than 40-50 km), as well as a combination of other synergistic effects (e.g., use of waste heat from cogeneration units, reducing watering costs when applying liquid digestate), digestate processing may be a cost-effective option.

A necessary prerequisite for the successful commercialization of digestate products may be the involvement of specialized fertilizers manufacturers in the creation of added value of humic substances, as well as a complex of macro-and micronutrients contained in the digestate. Organic carbon as a component of humic substances is an indispensable source of replenishment of humus in depleted soils, and therefore its content in the digestate should significantly complement its market value. The same applies to other important macro- and microelements, which are usually contained in the digestate in a balanced composition.

In general, awareness of the role of anaerobic digestaion of biomass and digestate application into soils in the circular economy and nutrient cycle, especially against the background of declining soil fertility in Ukraine, should trigger the creation of conditions for launching a full market for digestate fertilizers, including legislative regulation and possible mechanisms of financial incentives for producers and consumers of such fertilizers.

[1] Audrey Litterick, John Williams. Agricultural use of biosolids, composts, anaerobic digestates and other industrial organic fertilisers / TECHNICAL NOTE TN699 JANUARY 2019.

[2] KTBL, (2008). Umweltgerechte, innovative Verfahren zur Abtrennung von Nährstoffen aus Gülle und Gärrückständen – Technologischer Stand, Perspektiven und Entwicklungsmöglichkeiten. Studie im Auftrag der Deutschen Bundesstiftung Umwelt, erstellt durch das Kuratorium für Technik und Bauwesen in der Landwirtschaft (KTBL), Darmstadt, D, in Zusammenarbeit mit dem Institut für Technologie und Biosystemtechnik der Bundesforschungsanstalt für Landwirtschaft (FAL), Braunschweig, D.

Author: Petro Kucheruk – expert of Bioenergy Association of Ukraine

Read also:

Organic fertilizers in agriculture nutritions recycling

Consumption of organic fertilizers in Ukraine

The types of organic fertilizer produced in Ukraine and its market niches

Digestate post-treatment methods and derived products

Quality standardization and certification of digestate products