There are several technological schemes for harvesting grain corn [1]:

- Harvesting grain corn with corn combines with the further stationary treatment of ears:

1.1. without peeling of ears (separation of wrap);

1.2. with simultaneous peeling of ears (separation of wrap). - Harvesting grain corn with combine harvesters equipped with corn reapers;

- Collection of a mixture of grain and cobs with combines.

Currently, the main method for harvesting commercial corn is combine threshing of ears in the field, shredding and spreading of the cut biomass with the use of combine harvesters equipped with corn reapers. This method of harvesting grain corn is the most economically feasible. In comparison with harvesting ears, the method provides 1.8-2 times decrease in labor costs and 20-25% reduction in fuel consumption[2]. Only a few agricultural enterprises (seed factories) collect corn as non-threshed ears with the following stationary threshing, which makes it possible to collect cobs. The seed factories grow corn to obtain (hybrid) corn seeds as planting stock. Collection of mixture of grain and cobs with combines is not widespread in Ukraine yet.

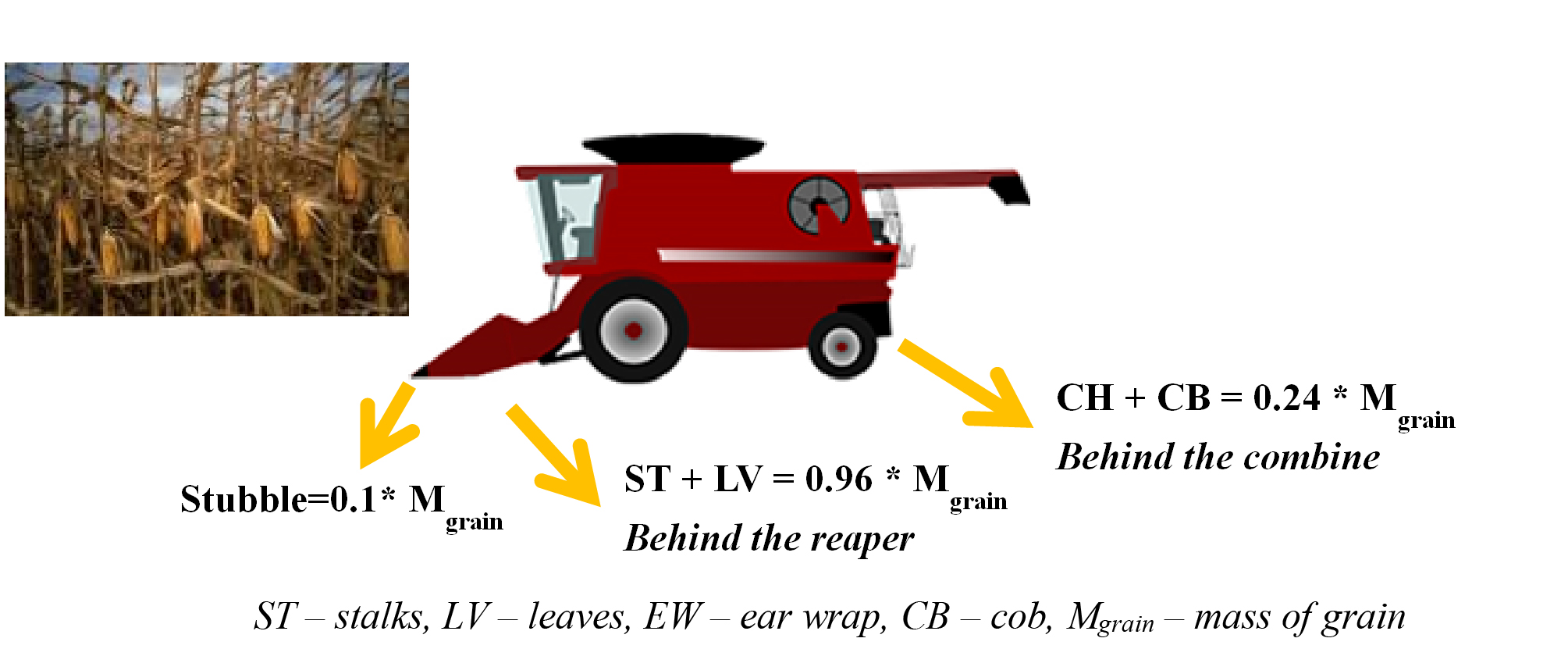

When harvesting corn with a combine harvester equipped with a corn reaper, the plant remains are redistributed as follows (Fig. 1): stubble remains (10% of the grain mass), remains behind the combine reaper (96% of the grain mass) and remains behind the combine harvester (24% of the grain mass).

Fig. 1 Formation of corn residues behind the combine harvester [1].

Technological schemes for harvesting corn stover (corn residues) can be divided into 4 main types for bales [3]:

- Single-pass harvesting system: combine with baler (ash content of collected corn stover is 3.5-4.5%; the same index is indicated for other technologies below).

- Combine with windrowing header + tractor with baler (7-9%).

- Combine + tractor with stalk-shredding windrower + tractor with baler (9-12%).

- Combine + tractor with stalk-shredder + tractor with rake + tractor with baler (up to 14%).

Of these technologies, for Ukraine we recommend “combine + tractor with stalk-shredding windrower + tractor with baler” (item c) in Fig. 2.

a) Single-pass harvesting system: combine with baler.

b) Combine with windrowing header + tractor with baler.

c) Combine + tractor with stalk-shredding windrower + tractor with baler

d) Combine + tractor with stalk-shredder + tractor with rake + tractor with baler

Fig. 2 Technological schemes for corn stover harvesting [3]

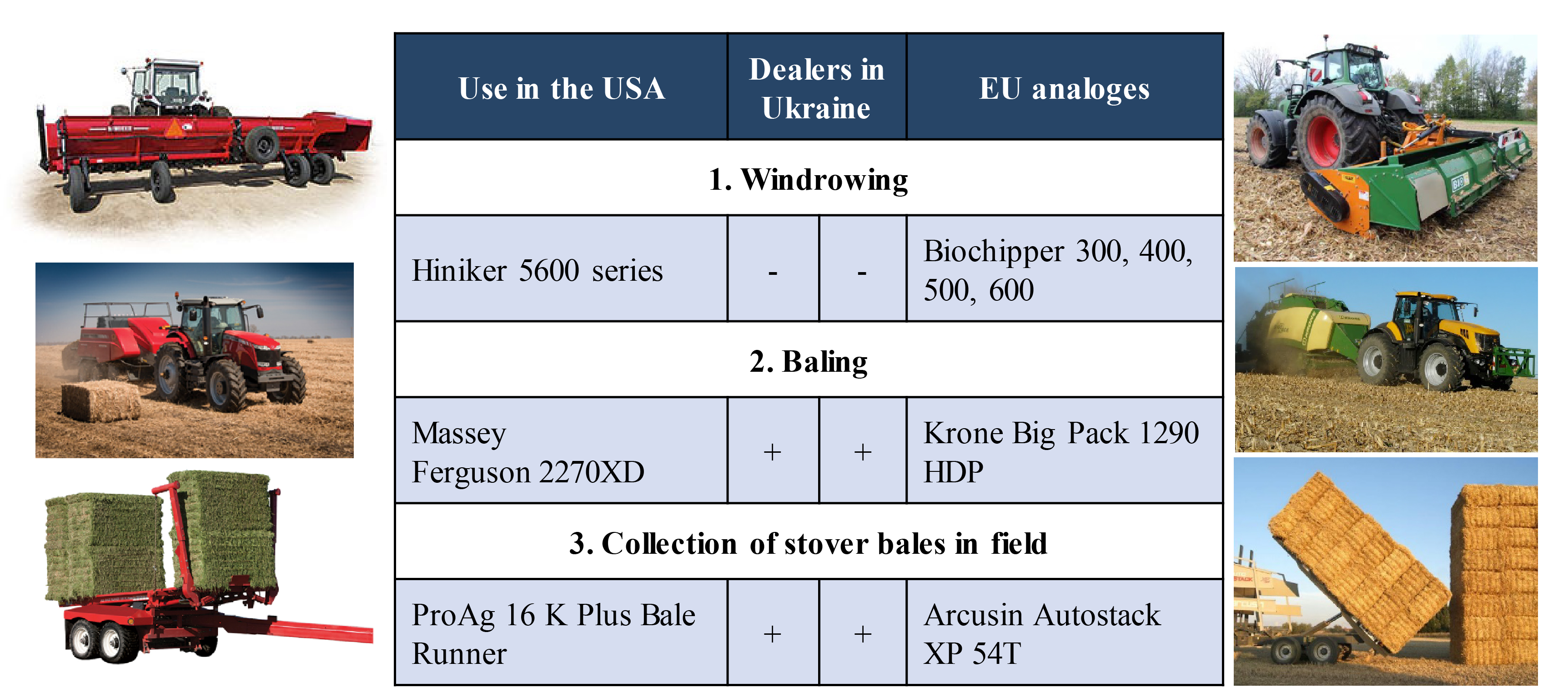

At different stages of the harvesting process, different models of equipment can be used (Fig. 3). Not all the types of required equipment are available in the Ukrainian market, but they can be ordered and imported through the dealers operating in Ukraine.

Fig. 3 Technological schemes for corn stover harvesting [3]

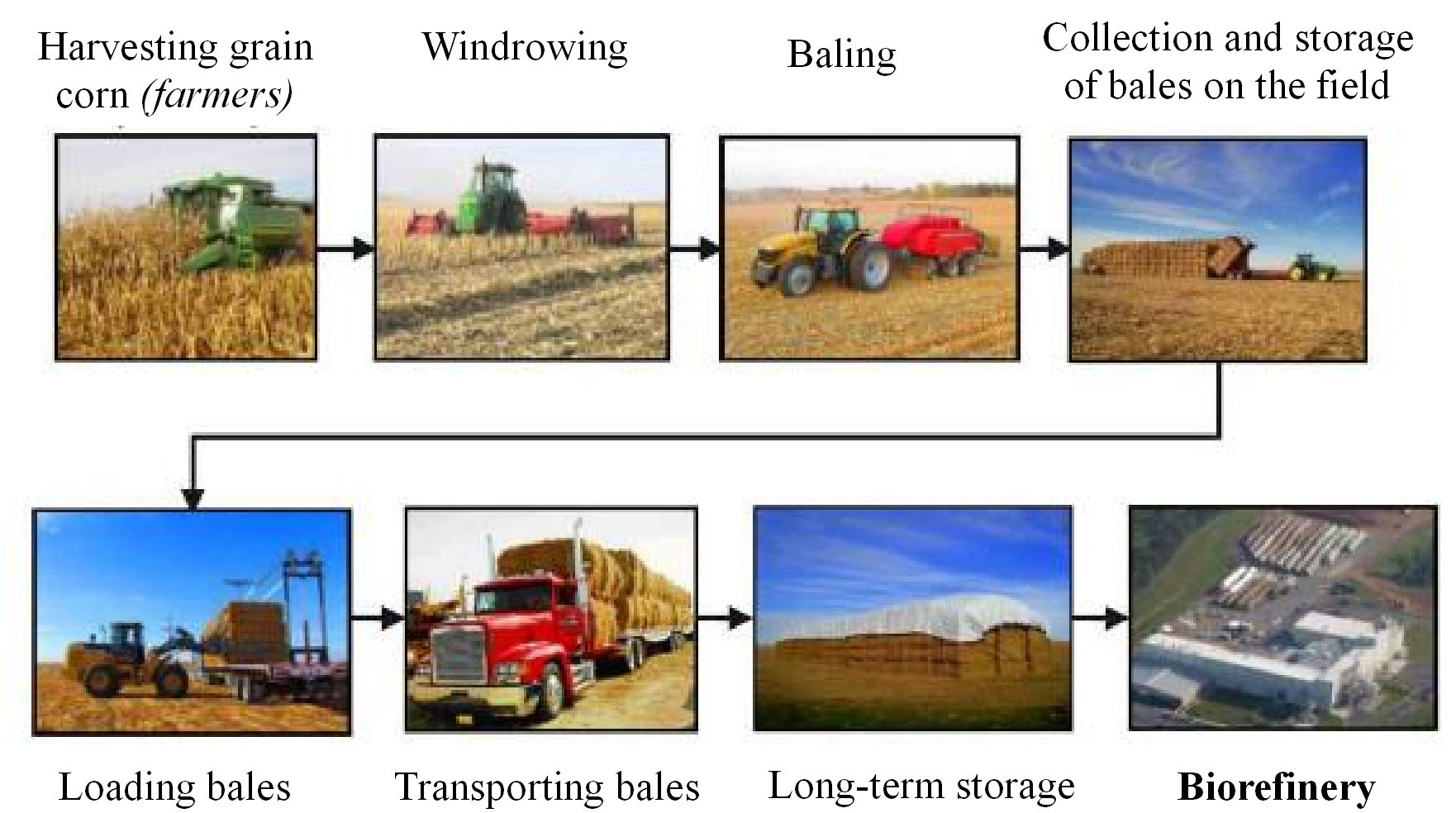

Example of the whole supply chain of corn residues (baled biomass) is presented in Fig. 4. It is the supply chain implemented and used by DuPont company (the USA) to provide its cellulosic ethanol plant with feedstock. Corn is harvested by local farmers while other operations are carried out by the plant staff.

Fig. 4 DuPont’s cellulosic ethanol plant model for corn stover supply chain [4].

Більше прикладів збору залишків кукурудзи – у наступних статтях.

Author: Semen Drahniev

[1] UABio’s Position Paper N 16 (2016) “Opportunities for harvesting by-products of grain corn for energy production in Ukraine” http://uabio.org/img/files/docs/position-paper-uabio-16-en.pdf

[2] Cherenkov A.V., Tsykov V.S., Dziubetskyi B.V., Shevchenko M.S. and other. Intensification of corn technologies – a guarantee for yield stabilization at 90-100 m.c./ha level (practical recommendations) // Dnepropetrovsk: NU Institute of Steppe zone agriculture NAASU, 2012 – 31 p.

[3] Report on “Analysis of utilisation of corn straw as an energy source” (2018). Prepared by SEC Biomass for EBRD against Contract C38842/1018/5362.

[4] DuPont Nevada Site Cellulosic Ethanol Facility Feedstock Collection Program http://www.dupont.com/content/dam/dupont/products-and-services/industrial-biotechnology/documents/IB-PDF-04-Feedstock_Collection_Program_2015.pdf

Read also:

State of the art of corn production in the world and in Ukraine

Сorn residues and harvesting in Ukraine

Potential of corn residues in Ukraine in 2018

Fuel characteristics and properties of corn residues