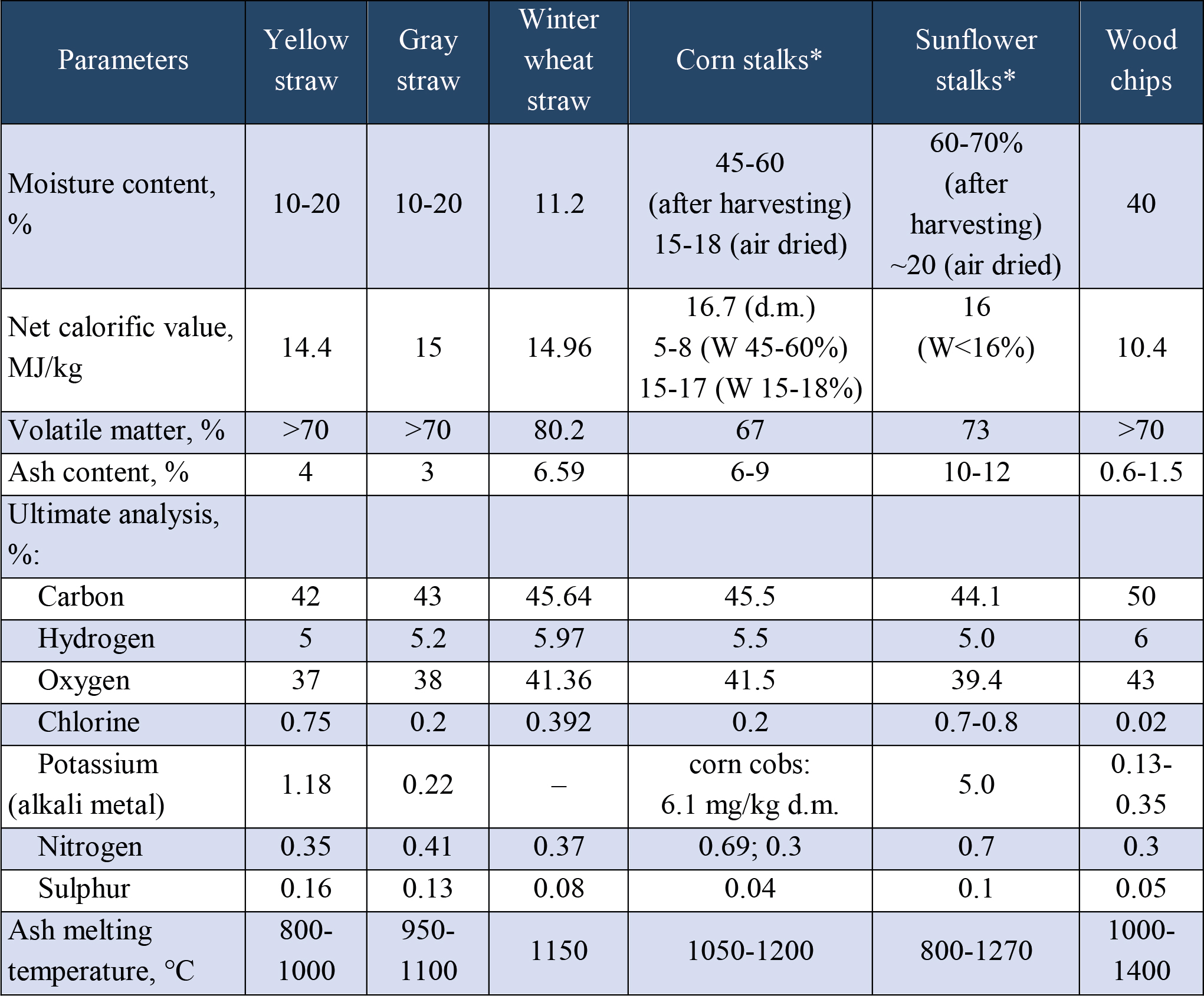

Сorn residues have quite good fuel properties which are close to those of wood fuel. Due to that, biofuels made from corn residues can be burnt in the equipment intended for wood biomass. Сharacteristics and fuel properties of corn stalks and its comparison of the properties with those of other agricultural residues and wood chips is shown in Table 1.

Ash content of corn stover is a major quality factor for further production of biofuels. The ash content depends on the type of harvesting technology as the amount of ash increases when biomass is contacting with soil. In view of this, there are two types of ash: structural and nonstructural[1]. Structural ash consists of inorganic substances of a crop, which remain after its burning. The usual ash content of corn straw is 3.5%. Unstructured ash is inorganic substances (mostly soil) that get into straw during harvesting, in particular when forming swaths and baling. Typical total ash content for multiple passes of agricultural machines when harvesting is 8-10%.

Table 1. Chemical composition and some properties of different types of biomass [2]

d.m. – dry matter; W – moisture content.

* Data for volatile matter, ash content, and ultimate analysis are based on dry matter.

As regards ash melting behaviour, corn straw is close to wood biomass, which provides better conditions for combustion compared to straw of cereal crops. For comparison: ash melting temperature for wood is about 1200 °C, and that of corn stalks is about 1100 ºC (see Table 1). In addition, corn straw contains less chlorine (0.2% d.m.) compared with fresh (“yellow”) straw of spiked cereal crops (0.75% d.m.). This is a positive factor for corn residues as fuel as chlorine compounds cause corrosion of steel elements of energy equipment.

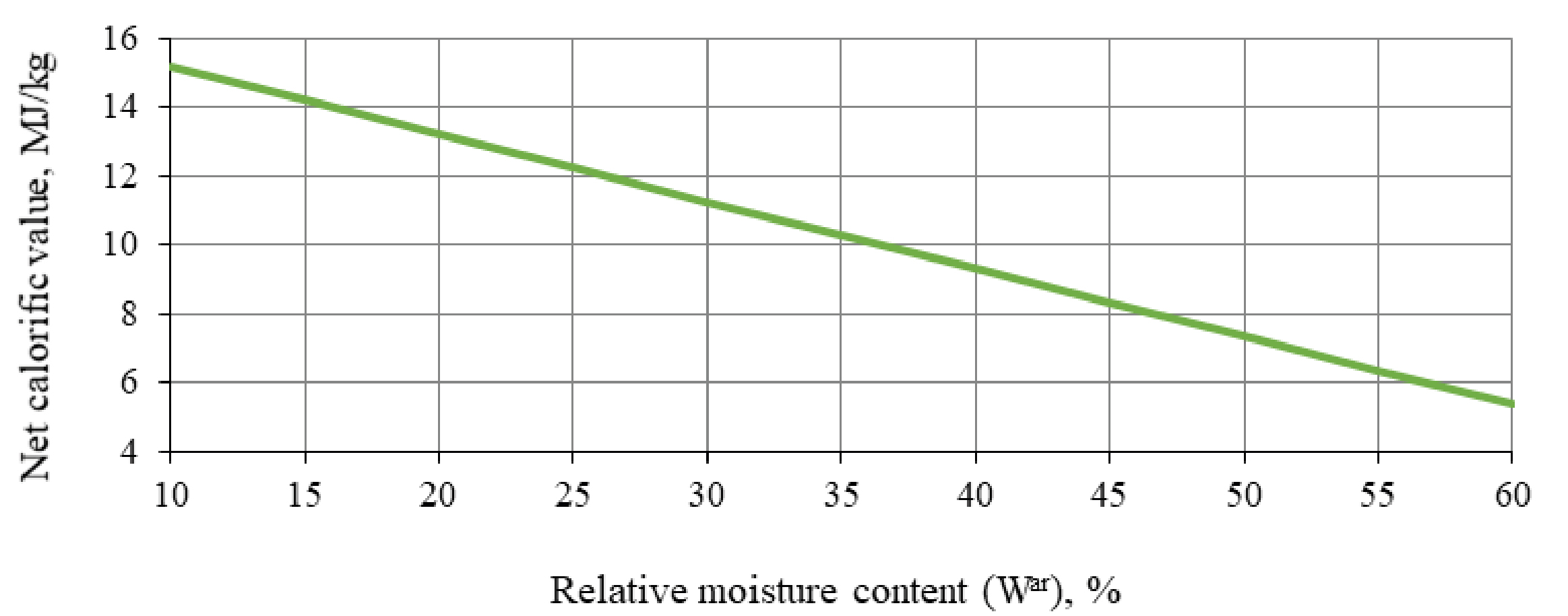

The elemental composition of corn straw is almost the same as that of straw of spiked cereal crops, so they have a comparable calorific value. The properties of straw strongly depend on the place of cultivation, harvesting time and weather, soil and fertilizers[3]. The biggest effect on the calorific value of corn residues is produced by their moisture content (Fig. 1).

Fig. 1. Net calorific value depending on the moisture content of corn stover (as-received basis) [4].

Authors: Semen Drahniev, Tetiana Zheliezna

[1] Brittany Schon, Matt Darr. Corn Stover Ash.

[2] UABio’s Position Paper N 16 (2016) “Opportunities for harvesting by-products of grain corn for energy production in Ukraine”

[3] Vyll Varesa. Handbook for biofuel consumer // Tallinn: Tallinn Technology University, 2005 – 183 p

[4] H. Liu. Biomass fuels for small and micro combined heat and power (CHP) systems: resources, conversion and applications (2011)

Read also:

State of the art of corn production in the world and in Ukraine

Сorn residues and harvesting in Ukraine

Potential of corn residues in Ukraine in 2018