A significant increase of agrobiomass usage in the energy sector, primarily non-grain, is provided by the Roadmap for Bioenergy Development of Ukraine until 2050, created under the EBRD program “Ukraine: sustainable innovations in the value chain in bioenergy”. However, in order to achieve the highest efficiency of bioenergy chains based on such agrobiomass, it is necessary to integrate modern technologies and take into account best practices. The experience of Italy is interesting for Ukraine.

Dr. Alessandro Suardi from the Italian research center CREA presented an important experience of straw harvesting during the meeting of the working group “Agrobiomass and Energy Crops” of the European Biomass Association (Bioenergy Europe).

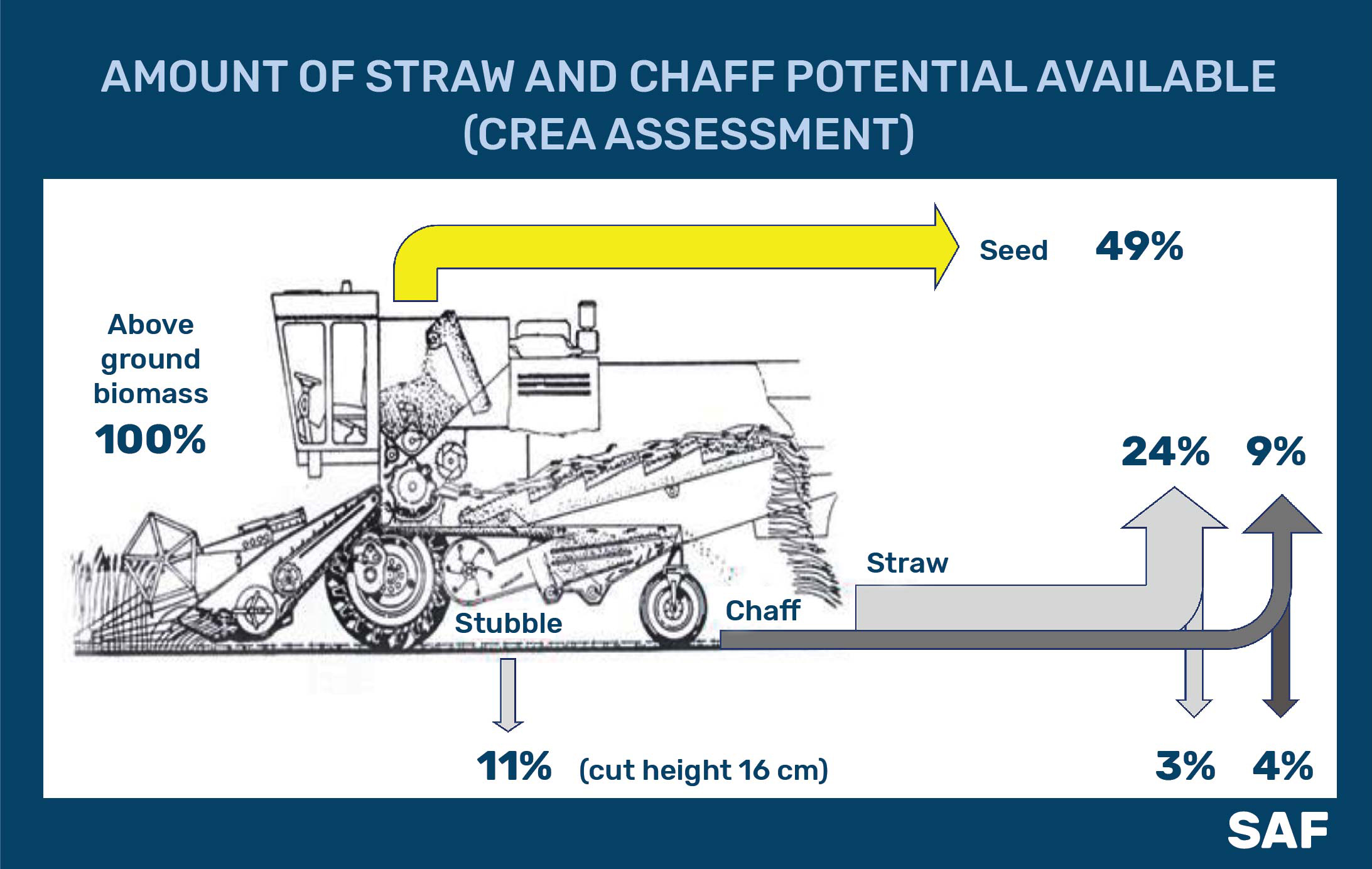

On average, 13.5 tons/ha of dry biomass (dm) were present in the field. 51% forms grains (6.8 tdm/ha); 37% – stem (5 tdm/ha); 0.84% – rachis and 10.16% – chaff (1.7 tdm/ha). 71% of straw is available for baling, which is 3.55 tdm/ha. 29% of stem (1.45 tdm/ha) isphysiologically lost due to cutting height of the combine (cut at 16 cm) and is incorporated in soil.

It should be noted that the chaff can be load above the straw windrow for further harvesting. The balance of biomass flows during grain harvesting by the combine according to CREA estimates is shown in the diagram below.

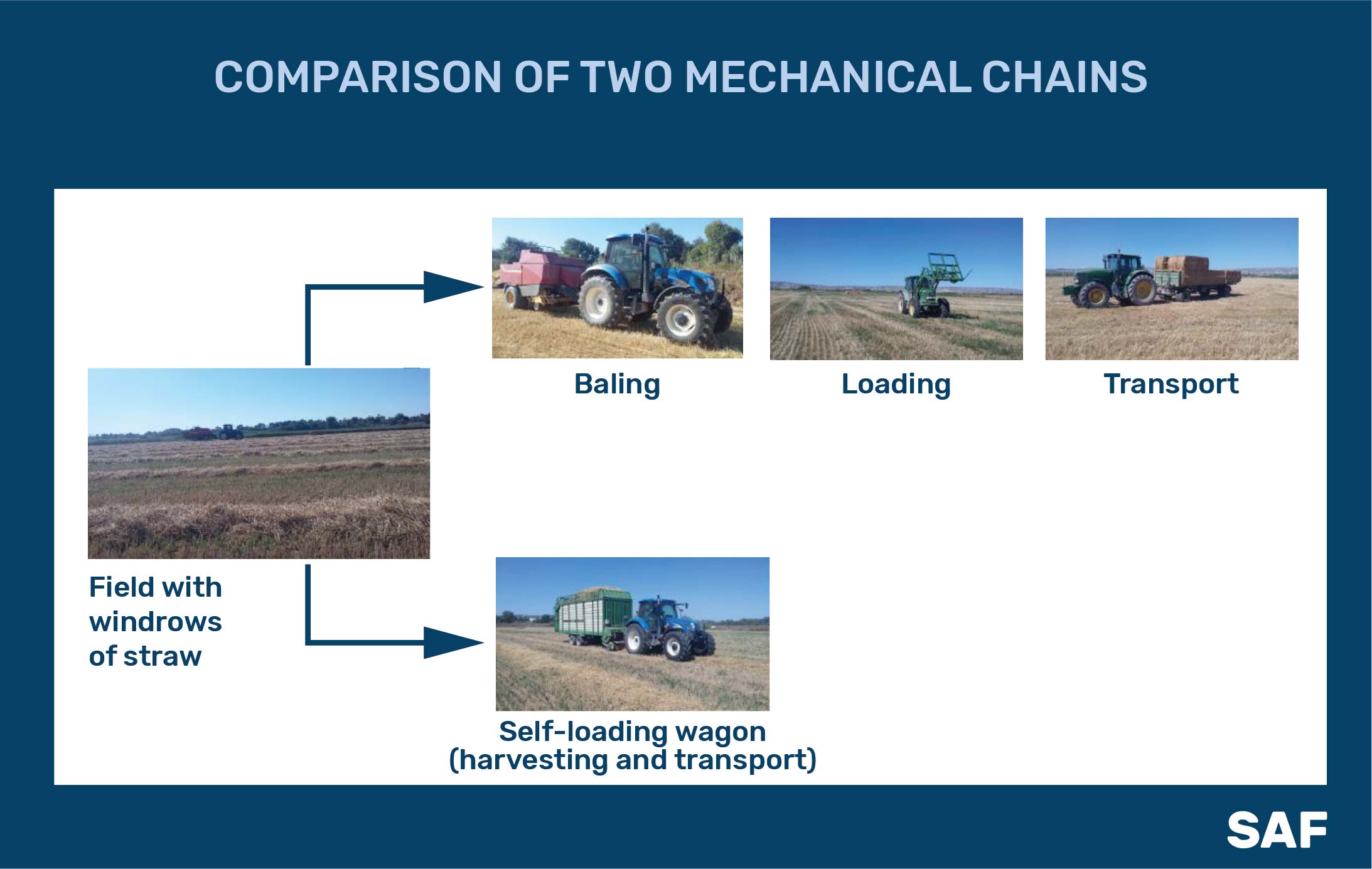

There are two basic technologies for harvesting the non-grain part of the crops:

- Picking up the straw from the field, compressing it into round or square bales, transporting the bales to the storage area. There are also some machines that just pick up the straw in loose form and transport it for densification.

- Self-loading forage wagons have increased in size and capacity, and have become fast and efficient harvesting machines.

The volume of round bales is from 0.7 to 2,5 m3, while their weight is 150-400 kg. The working speed of the tractor aggregated with a round baler is 4-7 km/h.

Square balers could be:

- Small – weighing 20-40 kg;

- Medium – weighing 80-250 kg;

- Big – weighing 500-600 kg.

The working speed of square balers is 5-6 km/h. The density of large bales exceeds 150 kg/m3. The working speed of the self-loading forage wagons is about 6 km/h, while the bulk density of straw is 12-25 kg/m3.

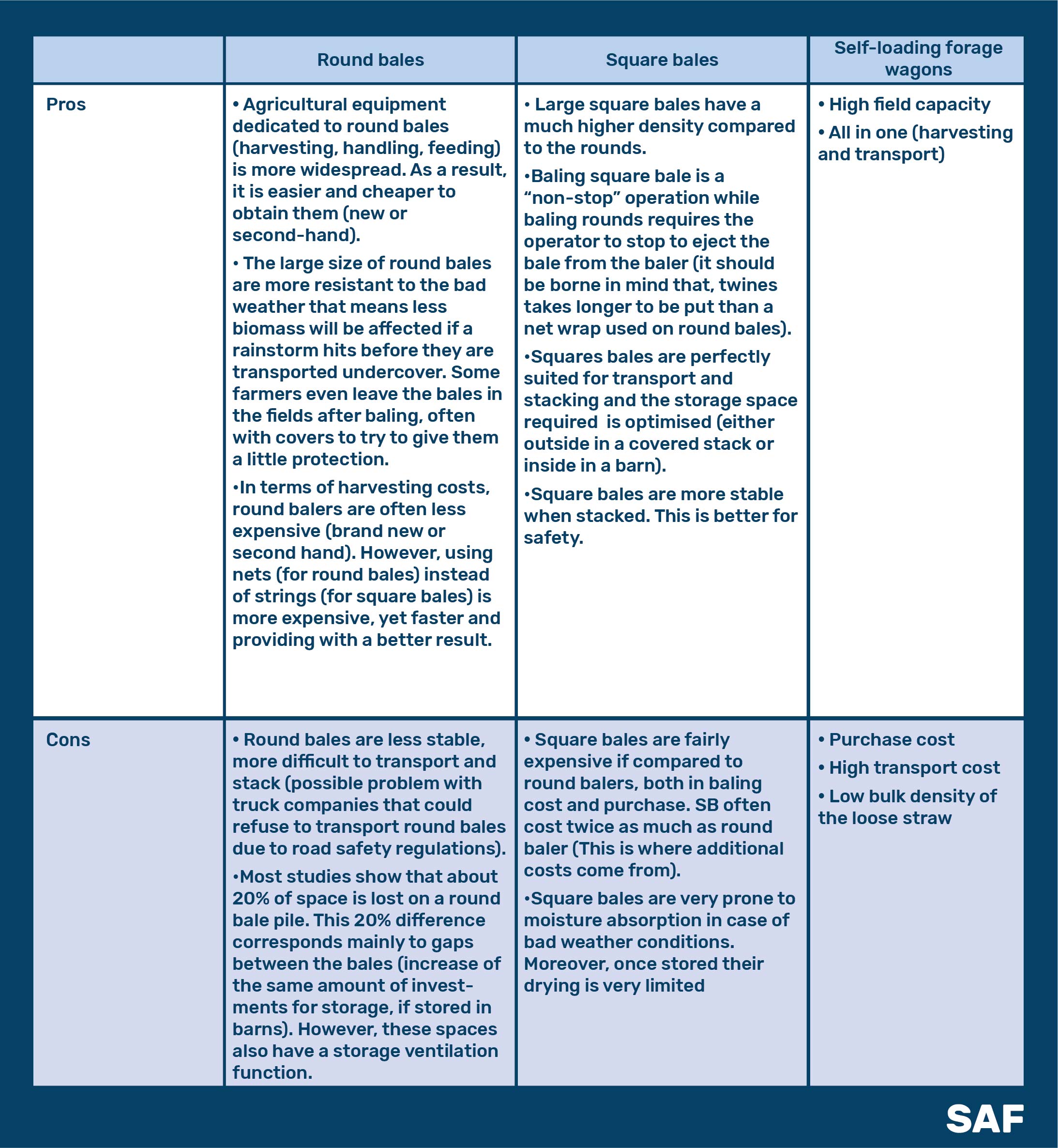

Let’s consider the advantages and disadvantages of straw harvesting using round balers, square balers, and self-loading wagons.

Key factors in the cost of straw harvesting:

- Nutrient removal (kg nutrient per tons of straw: 5.4 N –1.8 P2O5 –9.1 K2O);

- Baling (or loose straw harvesting);

- Handling & moving;

- Hauling;

- Delay in planting the next crop (% losses in yield per day).

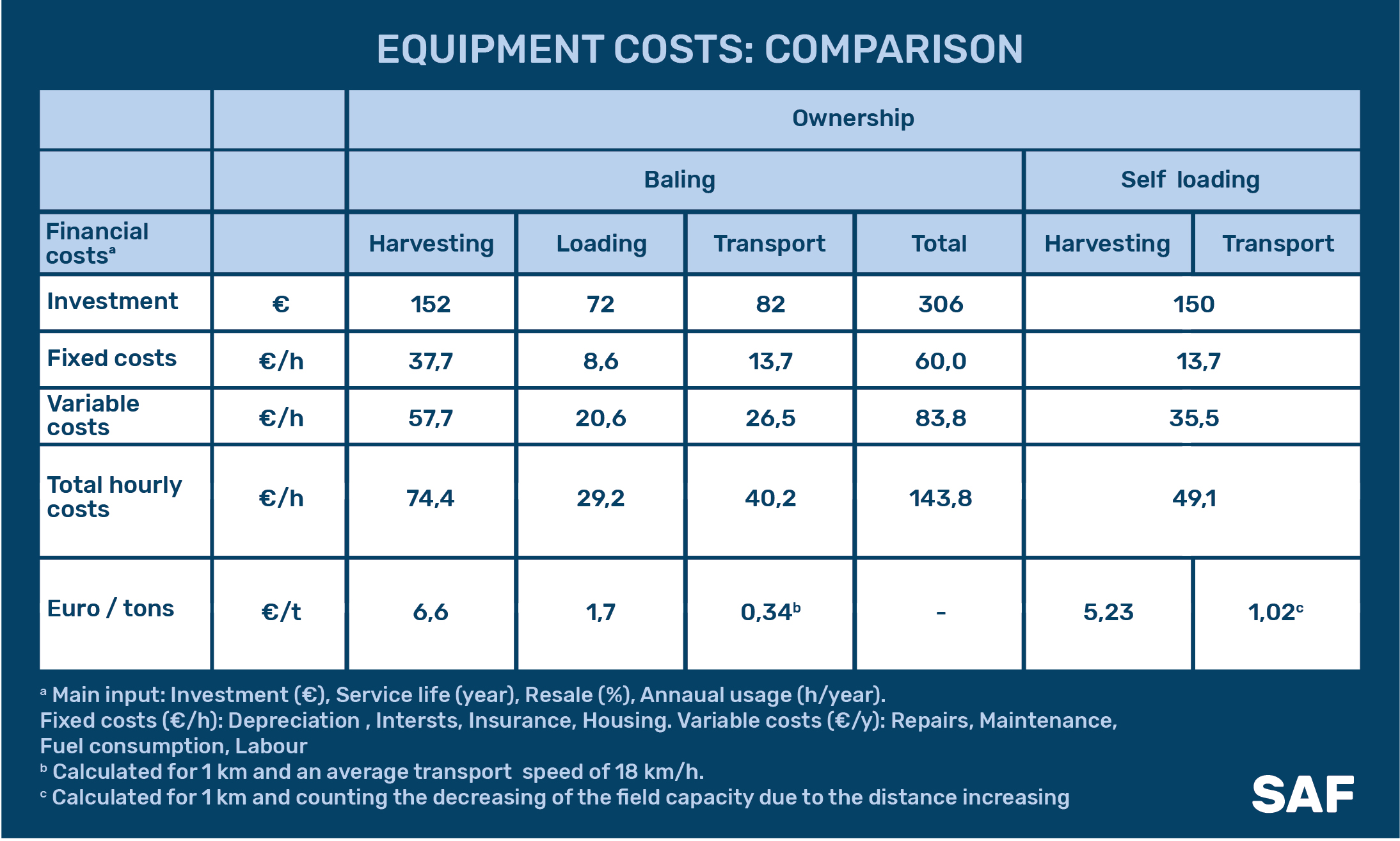

A cost comparison of straw harvesting with a square baler and a self-loading wagon in Italy is presented in the table below.

The test showed that the most suitable system for collecting cereal residues is the self-loading wagon if the transport of biomass to the biomass center remains within 11.4km.