The simplest way to use “raw” digestate as an organic fertilizer or soil improver is to apply it directly to the fields without any pre-treatment. However, such practices have a number of disadvantages and limitations and are therefore not common.

Biogas plantstypically operate continuously throughout the year, necessitating the accumulation of digestate for the periods between autumn and spring applications onto thefields. Prolonged storage in leaky reservoirs (lagoons) leads tothesolidssedimentationanditsaccumulation. Increasing the mass of “undigested” organic substances while long-term storage of digestate proportionally increases the emissions of methane greenhouse gas into the atmosphere(up to 5-10% of its potential in raw materials).Furthermore, given the relatively high content of coarse solids in the “raw” digestate, there are technical limitations on its distribution into soils, in fact leaving room only for surface splashing or spilling. At the same time much of readily available nitrogen for plants nutrition is being lost, and unpleasant odors are spread over large areas. Thus, pre-treatment of the “raw” digestate is, in most cases, necessary.

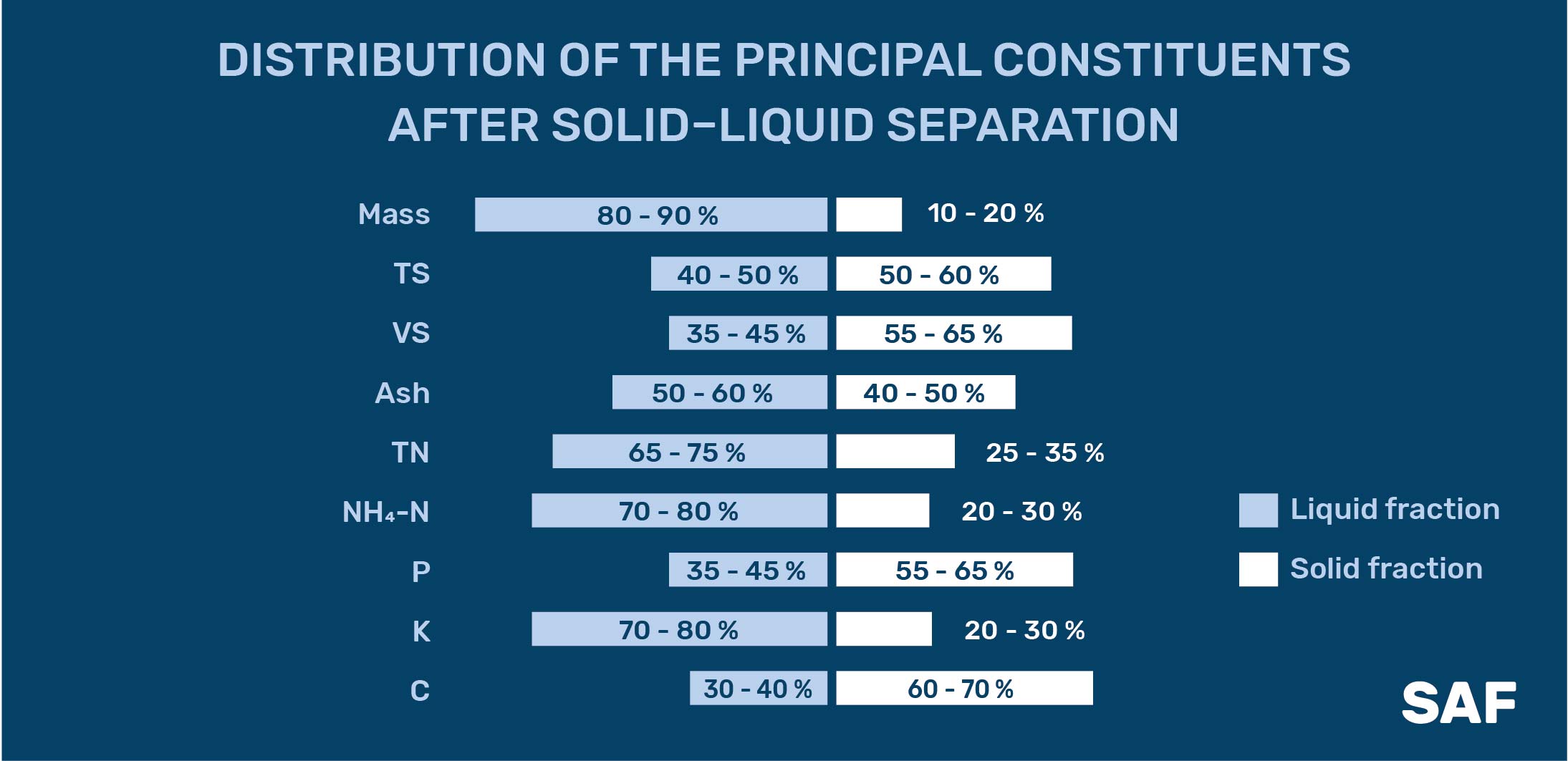

Typically, the first step of such treatment is the separation of the “raw” digestate into solid and liquid fractions, preferably in auger type separators. The volume of the liquid fraction can be reduced by 10-20%, depending on the type of feedstock and the type of separator. Separation leads to the formation of two products with different functionality: 1) a solid fraction with a solids content of 20-40%, enriched in carbon and phosphorus, and 2) a liquid fraction with a solids content of 1-8%, enriched in nitrogen and potassium (Fig. 1).

Figure 1 – Distribution of the principal constituents after solid–liquid separation [1]

The separation allows, in addition to partially reducing the required volume of digestate storages, to reduce residual methane emissions, to expand the list of possible technical means and methods of digestate application into soils, as well as to allow further processing of both solid and liquid fractions.

At most of biogas plants, as well in Ukraine, the processing of “raw” digestate is limited to the separation into liquid and solid fractions. Further processing of the digestate requires additional costs and therefore must be justified. The following are the main motivators for the additional treatment of the liquid/solid fraction of the digestate:

- to reduce the digestate transportation/application costs(achieved by reducing the volume of digestate);

- to overcome the limitation/restrictions on digestateapplication ontothe fields (insufficient area of own fields for digestateapplication, lack of own fields, high requirements for quality of digestate, etc.);

- to comply with the norms of nitrogen application per 1 ha of land (updated when Ukraine implements EU Nitrate Directive 91/676/EEC);

- economic feasibility of production and marketing of digestate products.

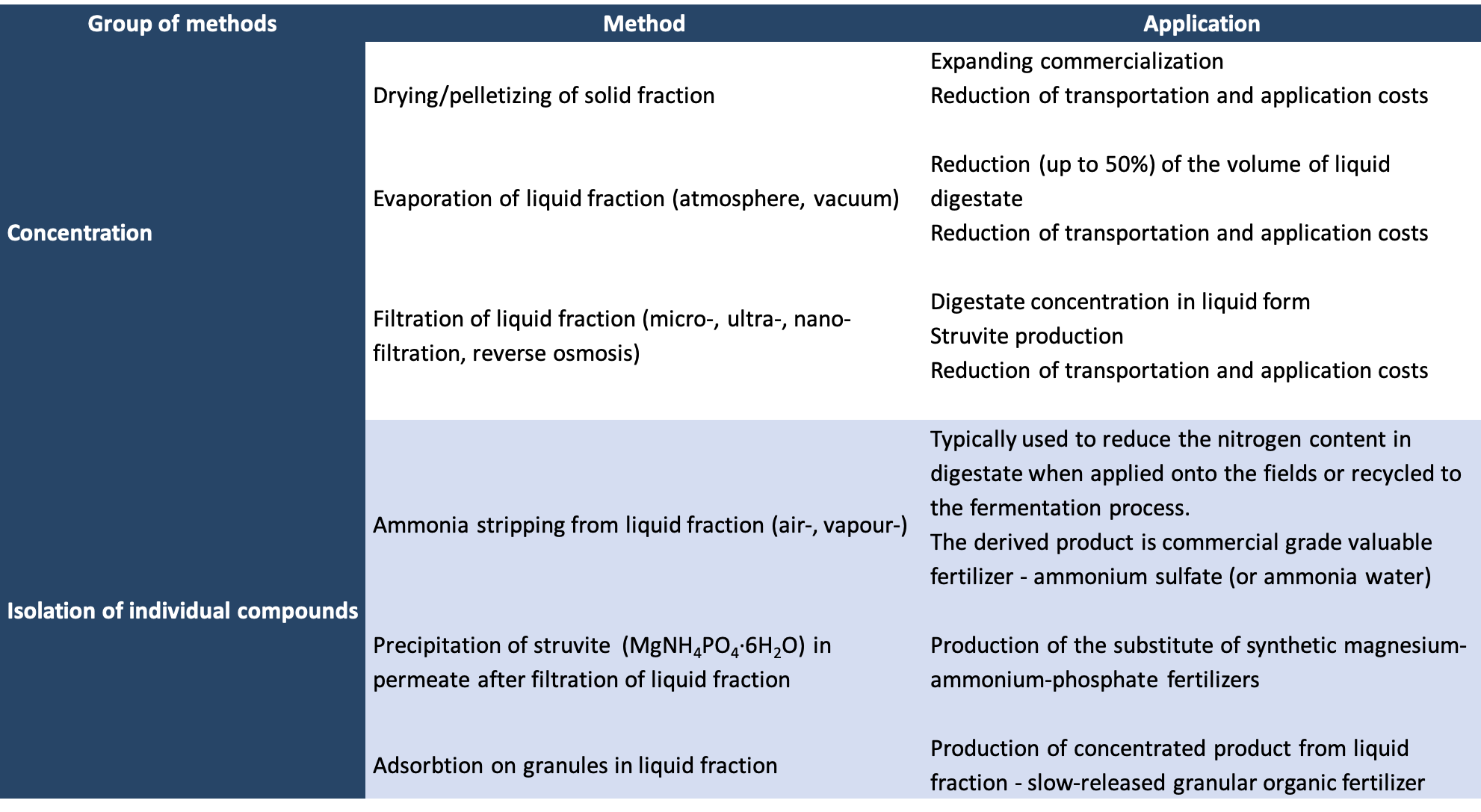

There are 2 basic directions for the treatment of the liquid / solid fraction of the digestate, namely: a) concentration; b) isolation of individual compounds(Table 1).

Table 1 – Methods of treatment of liquid/solid fraction of digestate

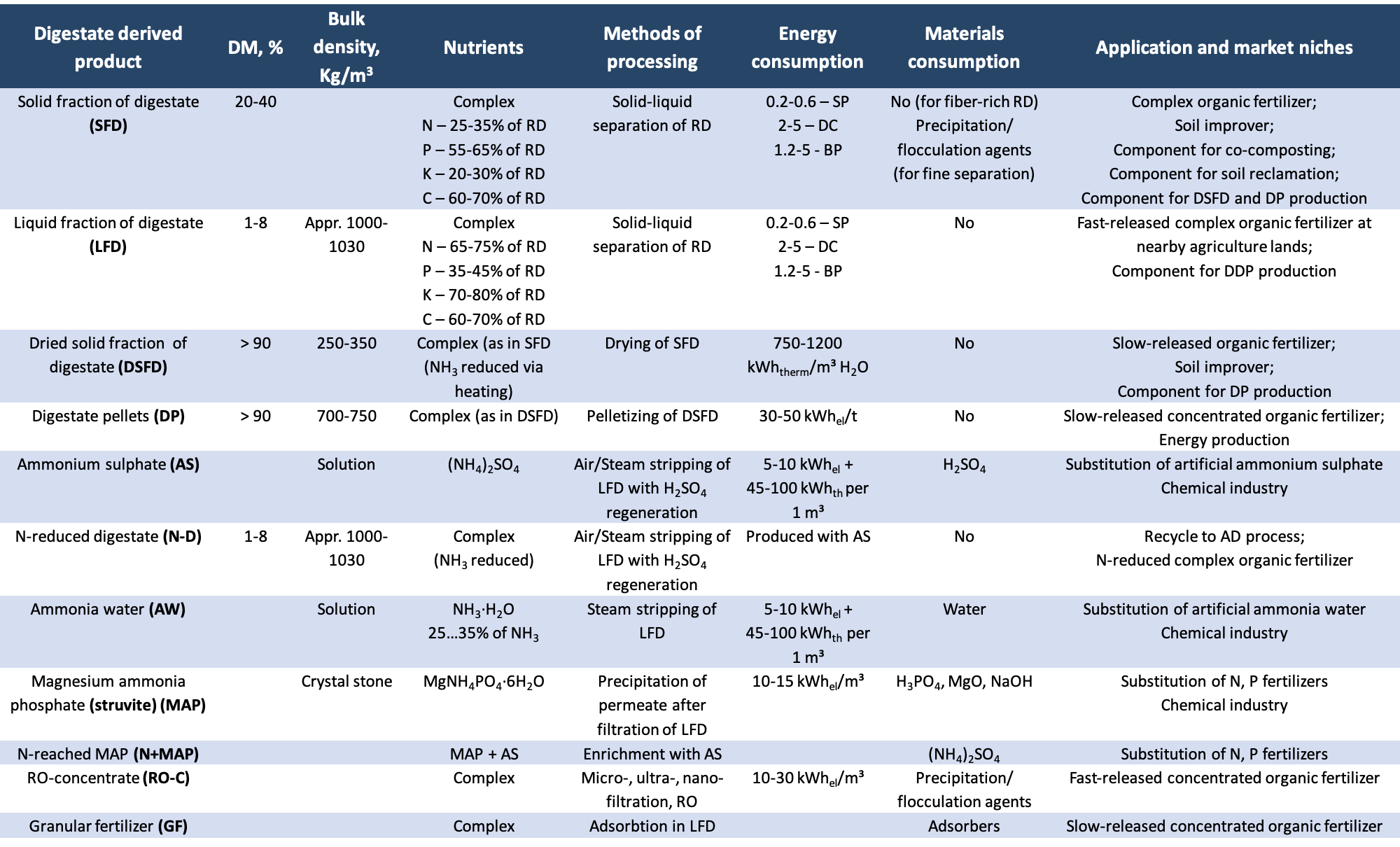

Using known methods of treatment there can be obtained at least 10 different derivatives from “raw” digestate (Table 2), including liquid/solid fraction, granules from both solid and liquid fractions, substitutes of commercial synthetic fertilizers (ammonium sulfate , ammonia water, magnesium ammonium phosphate (struvite)). All the production processes need electricity/heat and, in some processes, water, chemicals, flocculants and other auxiliary materials to be consumed. The enrichment/regulation of digestate derived products by adding macro- and micronutrients can rise up new opportunities for standardization of such fertilizers and facilitate their further commercialization.

Table 2 – The main types of digestate derived products (DDP)

[1] Bernhard Drosg et al. Nutrient Recovery by Biogas Digestate Processing / IEA Bioenergy, 2015

Author: Petro Kucheruk – expert of Bioenergy Association of Ukraine

Read also:

Organic fertilizers in agriculture nutritions recycling

Consumption of organic fertilizers in Ukraine

The types of organic fertilizer produced in Ukraine and its market niches