The global energy landscape is undergoing a transformative shift, as nations strive to reduce their reliance on fossil fuels and mitigate the impacts of climate change. The European Union’s commitment to achieving net-zero emissions by 2050 has spurred interest in renewable gases as part of its broader strategy for decarbonising the energy sector. Among the various renewable energy technologies, gasification has emerged as a promising solution, offering a versatile approach to converting organic materials into clean energy.

In December 2024, the European Biogas Association (EBA) released a report Gasification: diversification on biomass processing and waste utilization, which details the technology of gasification of biomass and waste in Europe.

Due to the size of the report, we will divide it into two parts. Currently, we are publishing the second part with more details on syngas, gasification plants in Europe, and economic aspects of biomass and waste gasification. The first part is already available for viewing on the SAF platform.

Syngas

Syngas energy density can be up to 30% lower than that of natural gas and cannot be injected as such in the natural gas grid. This leads to the integration of gasification with second-stage processing. Product gas can be upgraded for various end-use applications, each with its own advantages and challenges.

Gasification is usually combined with secondstage processing for the following end-uses:

- cogeneration into power and heat;

- water-gas shift into hydrogen;

- CH4 generation via methanation;

- Fischer-Tropsch (FT) into transportation fuels (e.g. diesel);

- high temperature industrial processes;

- chemical synthesis into balk chemicals (e.g. ethanol, methanol).

Energy Efficiency:

- Highest Efficiency: Direct CHP (80-90% overall efficiency with heat recovery).

- Moderate Efficiency: Methanation (60-70% and up to 85% with heat recovery) and hydrogen upgrading (60-70%).

- Lower Efficiency: Fischer-Tropsch fuels (45-55%), high T industrial processes (40-65%) and chemical synthesis (40-60%).

Biochar

The valorisation of gasification byproducts makes the process more economically viable and environmentally sustainable, while also

opening up new avenues for technological innovation and resource utilisation. Even if most of the gasification applications help maximise syngas production, some gasifiers may also produce a small amount of biochar. It could be further used for energy generation or considered as a commodity material.

Biochar. Source: GrowNextGen.

Biochar is a solid material similar to coal, is based on biomass and can be considered as a carbon sink. It is estimated that around 2.0-2.6 tonnes of CO2 are trapped per tonne of biochar. As long as it is not used thermally, carbon is preserved for hundreds of years. It is a valuable bioproduct whose application offers significant benefits beyond soil amendment.

Gasification plants in Europe

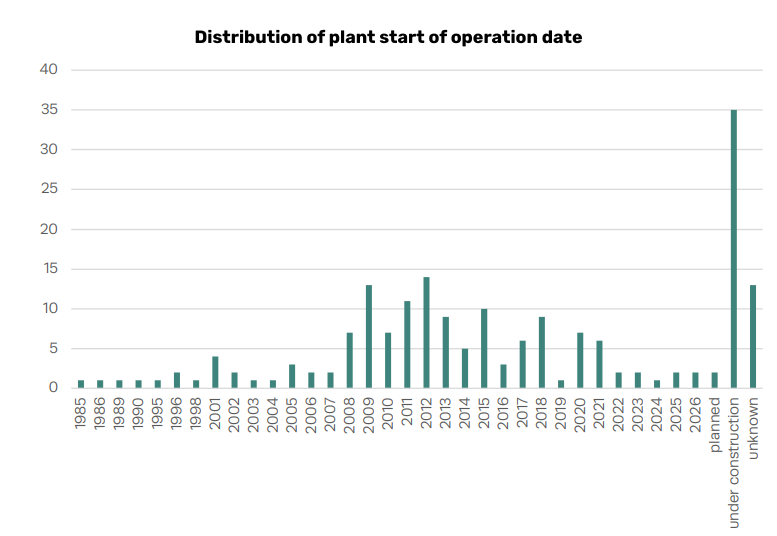

As of 2023, in Europe there were approximately 141 existing biomass and waste gasification installations and 54 installations at different stages of development or with an unknown construction date. Germany is the leading country regarding the number of installations, with 61. The majority of the plants are in the pilot or demo stage. Several plants are located in research centres and universities, as they are built around innovative technologies. The country with the second largest number of projects is France. In France, five plants are in operation, while 34 plants are under development. Finland and Italy share third place in the number of installations (18 each).

Source: EBA.

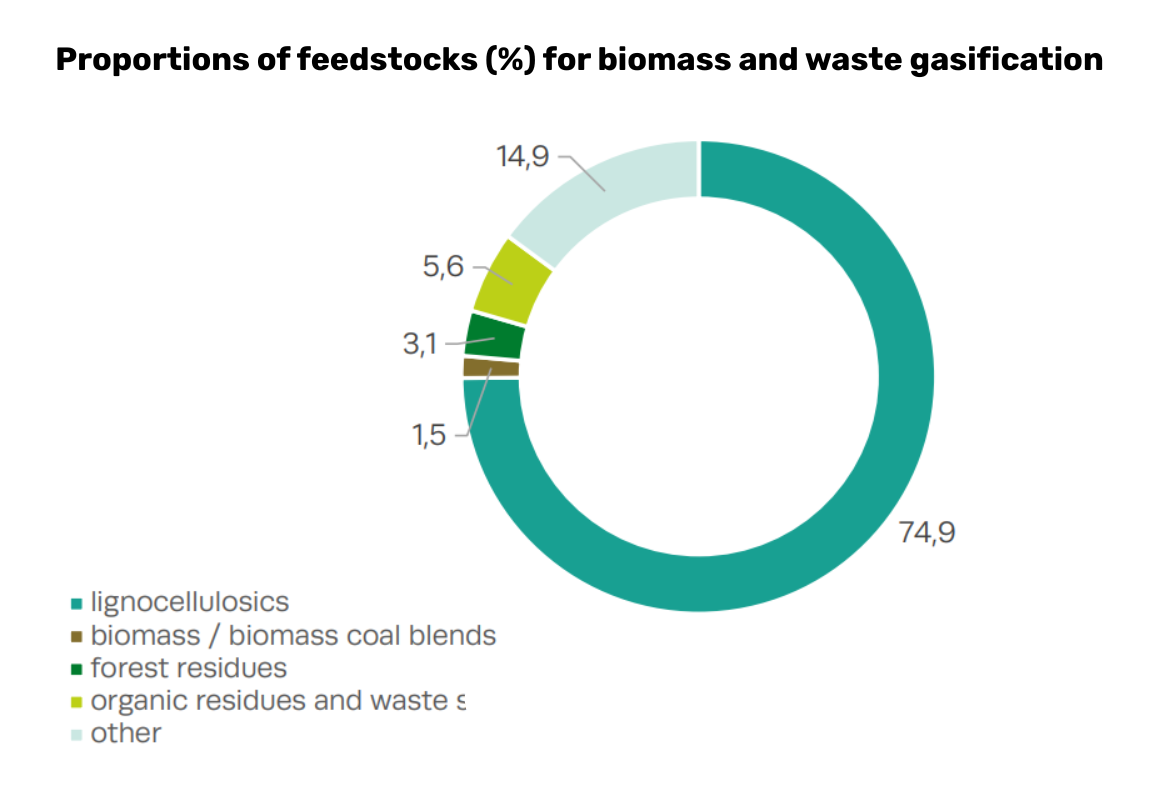

Feedstock

The feedstocks used in thermal gasification play a crucial role in determining the process efficiency and the quality of the produced syngas. A wide variety of biomass resources can be utilised, including agricultural residues, forestry wastes, energy crops and municipal solid waste (MSW).

Agricultural residues are typically characterised by high cellulose and hemicellulose content, which can be effectively converted into syngas. Forestry wastes represent a significant source of biomass for gasification in regions with substantial forestry industries. MSW as a feedstock for gasification offers the dual benefits of waste management and energy recovery. The heterogeneous nature of MSW presents challenges in terms of feedstock preparation and process control, but advancements in sorting and pre-treatment technologies have improved its viability.

Source: EBA.

Economic aspects of gasification

The biomass and waste gasification market presents significant opportunities for growth and investment, driven by the need for sustainable energy solutions and effective waste management. While the market faces challenges such as high capital costs, technological risks and regulatory uncertainty, the potential economic benefits and positive environmental impact make gasification an attractive investment area.

The continued development and adoption of gasification technologies, supported by favourable policies and public-private partnerships, are essential for realising the full potential of this market. As the global push towards renewable energy and sustainability intensifies, biomass and waste gasification will play a crucial role in the transition to a cleaner and more resilient energy future.

Key advantages of the market

- Environmental Regulations: worldwide implementation of stringent regulations to reduce greenhouse gas emissions and promote renewable energy encourage the adoption of gasification technologies to convert waste and biomass into clean energy.

- Energy Security: countries are increasingly looking to diversify their energy mix to include renewable sources. Gasification

offers a reliable and sustainable energy source, reducing dependence on fossil fuels and enhancing energy security. - Waste Management: effective waste management is a significant challenge for urban areas. Gasification provides a solution by converting municipal solid waste (MSW) into valuable energy, reducing landfill use and mitigating environmental pollution.

- Technological Advancements: innovations in gasification technologies are improving efficiency, reducing costs and expanding the range of feedstocks that can be processed.

- Supply and Demand: the availability and cost of feedstocks, such as agricultural residues, municipal waste and forestry byproducts, influence the economic viability of gasification projects.

Key challenges and risks

- High Capital Costs: initial investment for setting up gasification plants is high, which can be a barrier to entry for many investors.

- Technological Risks: as gasification technologies are complex and require advanced engineering and operational expertise, the risk of technological failures and operational issues can deter investment.

- Regulatory Uncertainty: changes in government policies and regulations can impact the gasification market, hence investors need to navigate regulatory risks and ensure compliance with evolving environmental standards.

- Market Competition: the renewable energy sector is highly competitive in relation to market share. Gasification technologies must compete with solar, wind and other renewable energy sources for investment and adoption.

In summary, biomass and waste gasification presents a promising avenue for renewable energy production, with substantial economic potential. However, there is an urgent necessity for policies and financial incentives for biomass gasification projects. According to estimate provided in the European Commission’s report, under current market conditions, the energy contribution of gasification technologies can reach 0.62 bcm by 2030 and 9.9 bcm by 2050. However, according to Guidehouse modelling, the potential for biomethane production from thermal gasification can reach 37 bcm. Accelerated growth is expected after 2030 when all currently developing technologies will enter the technologically mature stage, the production chain will be fully optimised and all appropriate feedstocks (including novel feedstocks) will be utilised accordingly.