Solid biofuels from agrobiomass are generally considered more difficult to burn than wood biomass. Therefore, boiler manufacturers face a difficult task: to achieve high efficiency and low emissions when using biofuels from agrobiomass.

Agrobiomass can be sorted into three large groups:

- agricultural residues (for example, straw, corn, grape vine);

- agro-industrial residues (for example, sunflower husk);

- dedicated energy crops (for example, miscanthus, energy willow, and poplar).

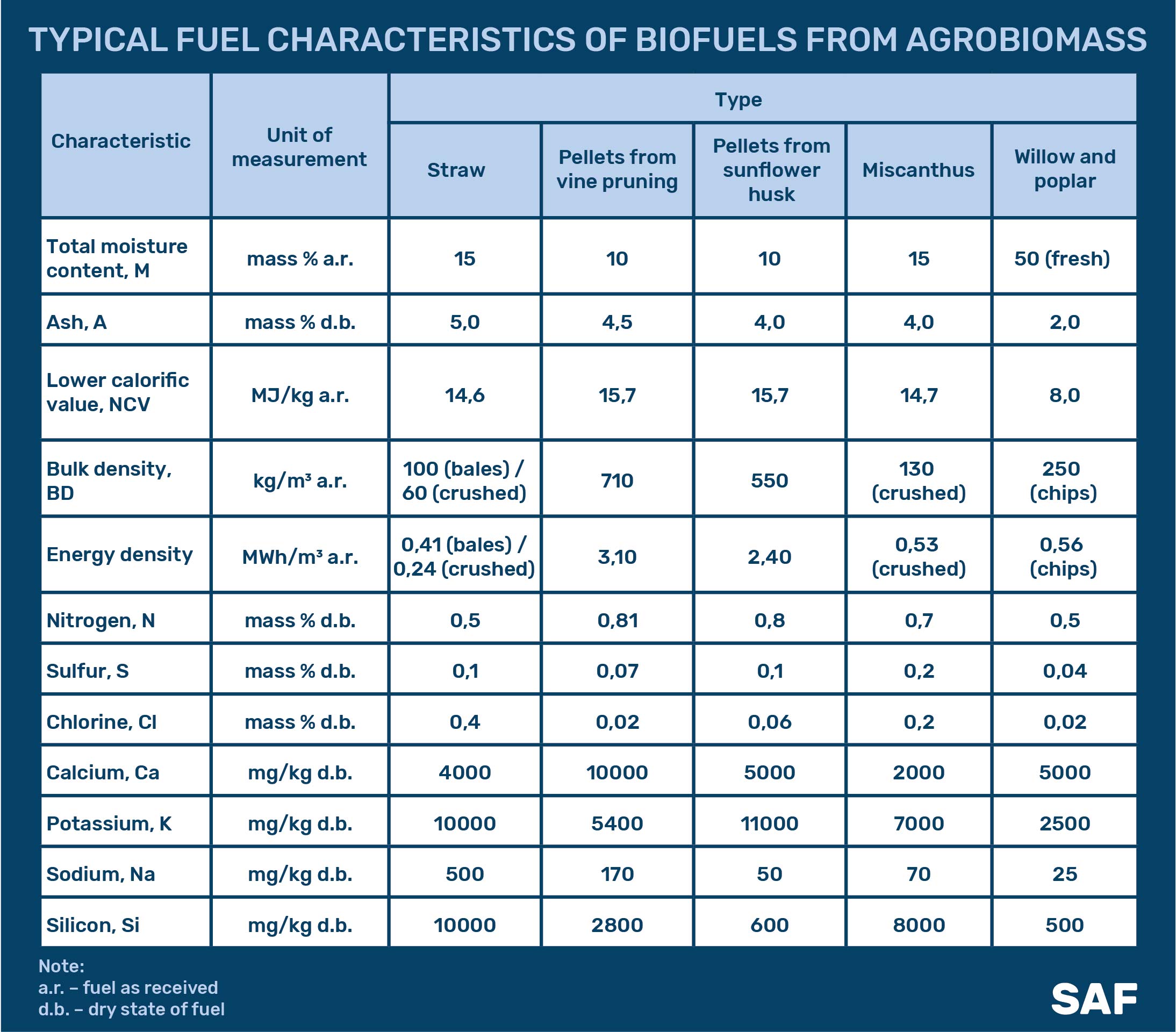

It should be noted that these groups of agrobiomass have a variety of fuel characteristics, which are influenced by many factors, including crop variety, farming techniques, soil and weather conditions, harvesting dates, harvesting technology, and more.

Typical fuel characteristics of biofuels from agrobiomass are presented in the table.

More information on typical changes in these properties can be found in State Standard of Ukraine EN ISO 17225-1: 2019 “Solid biofuels. Technical characteristics and fuel classes. Part 1. General requirements “.

Effective combustion of agrobiomass is often achieved through the comprehensive application of a number of measures with strict requirements for quality, fuel composition (humidity, ash content, size, etc.), the choice of special equipment for fuel use, installation of additional gas cleaning equipment and commissioning or thermal tests that provide the best environmental indicators of the equipment and ensure the permissible emissions of pollutants into the atmosphere.

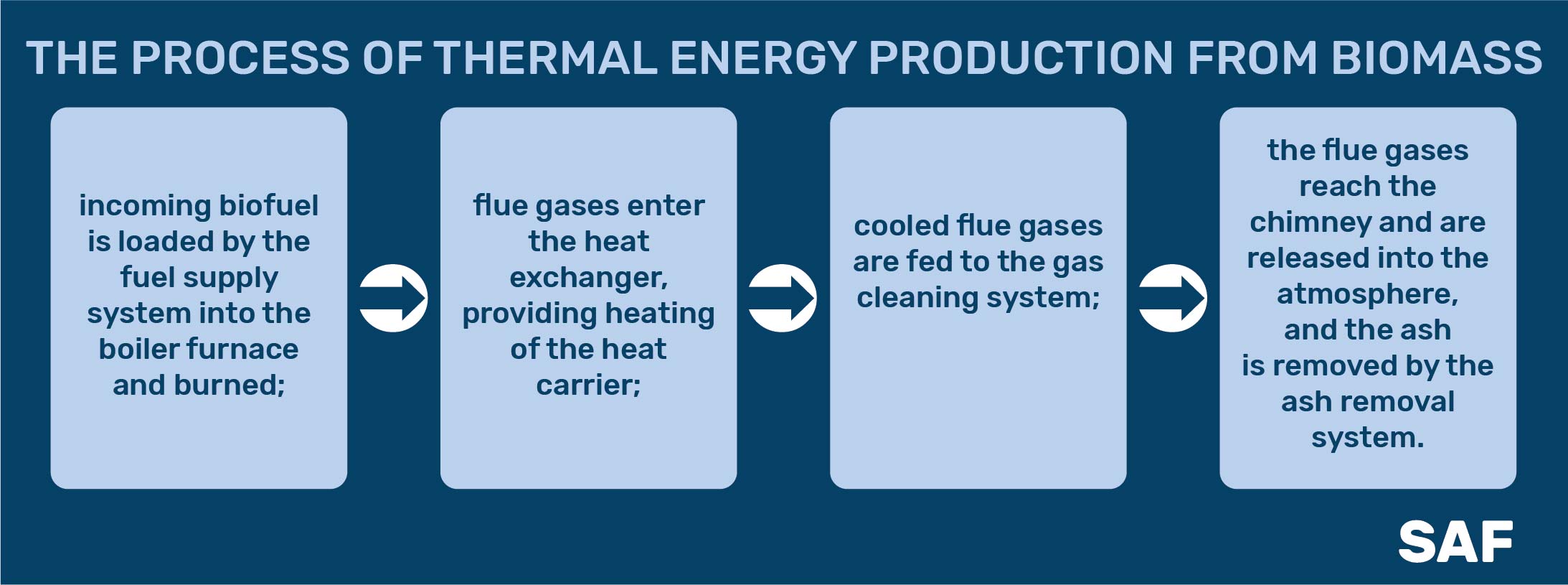

In the process of thermal energy production from biomass, the following stages can be distinguished:

- incoming biofuel is loaded by the fuel supply system into the boiler furnace and burned;

- flue gases enter the heat exchanger, providing heating of the heat carrier;

- cooled flue gases are fed to the gas cleaning system;

- the flue gases reach the chimney and are released into the atmosphere, and the ash is removed by the ash removal system.

Simple boilers, such as those with a fixed grate, may not be suitable for efficient agrobiomass combustion. But there are many modern boilers that are specially designed to meet the specific characteristics of agrobiomass biofuels, from the fuel supply and combustion system to flue gas cleaning equipment.

In process of selecting the appropriate boiler, each of its components – fuel supply and combustion systems, heat exchanger, ash removal systems, flue gas control, and purification systems – must be compatible with the specific properties of solid biofuel from agrobiomass. Typically, such systems are controlled automatically, provide multi-stage air supply and have a movable grate, which allows efficient and complete combustion of such biofuels, as well as automatically clean the heat exchangers from deposits to prevent the formation of ash and corrosion.

Hydraulic movable floor

Most modern biomass boilers have an automatic fuel supply system. Depending on the form of agrobiomass available on the market and the method of its storage, different fuel supply systems may be required.

The most common fuel supply systems used in agrobiomass heating systems:

- fuel supply system of granular biofuels (screw feed, screw feed with mixer, suction system, and screw conveyor);

- wood chips/lump biofuel supply system (unloading mixer with an auger, hydraulic movable floor (“living bottom”);

- fuel supply system for whole bales (bale pusher with hydraulic piston, conveyor with a shredder).

For small and medium-sized thermal energy systems from biomass, fixed bed combustion is one of the most common technologies, as it can use a wide range of fuels and use less complex preparation and processing. The primary air passes through a fixed layer of fuel, in which the coke residue is dried, gasified, and burned. Gases formed during combustion are burned after the second addition of air, usually in the combustion zone, separated from the fuel layer. This separate supply of primary and secondary air is called “staged combustion”.

Various technologies of fireboxes with a fixed layer are available:

- fixed gratings,

- movable chain lattices,

- push grids,

- rotating grilles,

- vibrating gratings,

- burners with lower feed.

Boiler with inclined-pushing grate

All these technologies have certain advantages and disadvantages depending on the properties of the fuel, so at the planning stage of the project they need to be carefully selected. A well-designed and well-controlled grille ensures even distribution of fuel and a layer of coke residue over the entire surface of the grille.

The primary air should be divided into sections to be able to regulate the specific amounts of air according to the requirements of different zones, allowing the furnace to operate at partial loads and control the primary air ratio needed to provide a reducing atmosphere above the grate (required for low nitrogen).

The gases released during the biomass conversion process on the grate continue to burn above the bed, and secondary air plays an important role in mixing, combustion and emissions. An advanced secondary air supply system is one of the most important elements in optimizing the combustion of the gas phase. The combustion chamber can be water-cooled or have a refractory lining with external water or air cooling, which is especially important when burning biofuels from agrobiomass with a low melting point of ash, in particular straw.

Pneumatic heat exchanger cleaning system

Heat exchangers can be located both vertically and horizontally. Small and medium-sized biomass boilers usually use heat exchangers with chimneys (hot flue gases move inside the pipes, while water flows in the volume around them).

A clean heat exchanger is crucial for the life cycle of the boiler and the efficiency of its operation on agrobiomass.

There are two main technologies for cleaning the heat exchanger:

- by mechanical means,

- using compressed air.

Automated ash removal system

Given the high content of ash in agrobiomass to ensure long-term and continuous operation of boilers, it is necessary to ensure the proper choice of the ash removal system.

Ash removal is usually performed automatically by a special auger. Floor ash and ash from cleaning the heat exchanger are collected in an ash box or container. In addition, additional ash compaction systems are sometimes used, which allow extending the intervals of its accumulation.

Although the operation of modern agrobiomass boilers is aimed at achieving not only high combustion efficiency but also low emissions, to meet the requirements of various regulations on emission values, it is necessary to use additional flue gas cleaning systems, including cyclones, fabric, or electrostatic precipitators.

Source: AgroBioHeat report “Agrobiomass fuels and utilization systems”