Digestate is the product of organic materials bioconversion in the process of methane fermentation resulting in the organic matter complex decomposes to simpler organic compounds, mineralized substances, microbial biomass, and biogas, that is consisting mainly of methane (55-70%) and carbon dioxide (30-45%).

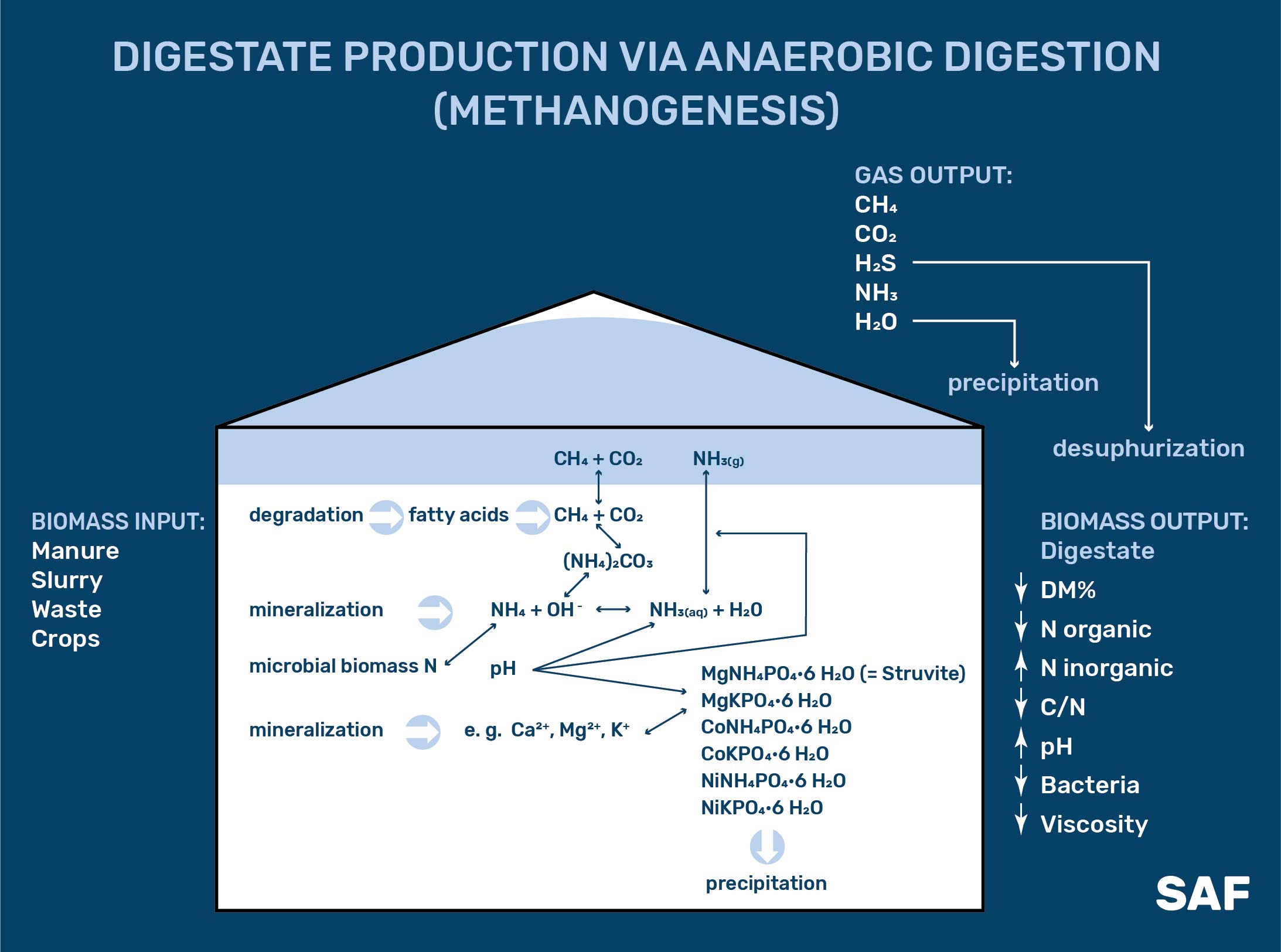

The typical technology for biogas production from agrarian materials (manure, litter, corn silage, sugar beet pulp, crop residues, etc.) is methane fermentation in semi-flow type bioreactors (Fig. 1).

Figure 1 – Digestate production via anaerobic digestion (methanogenesis) [1]

As a result of organic matter decomposition, mineralization processes and biogas release in the digestate comparing with input raw material:

- Dry matter content goes up, consequently, water content and viscosity go down. Digestate water content is generally 94-96%, although it can range from 92 to 99%.

- Ammonia nitrogen content (directly available for plant nutrition) increases by 10-70%. The increase of ammonia nitrogen depends on its initial content in the raw material, the smaller drop in the fermentation process belongs to pig and cattle slurry, the larger increase belongs to food waste and vegetable materials.

- The C/N ratio decreases by releasing part of the carbon with biogas. The optimal for the methane fermentation process C/N ratio of 20-30 is also considered optimal for soil biocenosis.

- The content of pathogenic microflora and viable weed seeds goes down as a result of simultaneous exposure to temperature (typically 38-40 oC) and acidity in the bioreactor for a long time (at least 25-30 days).

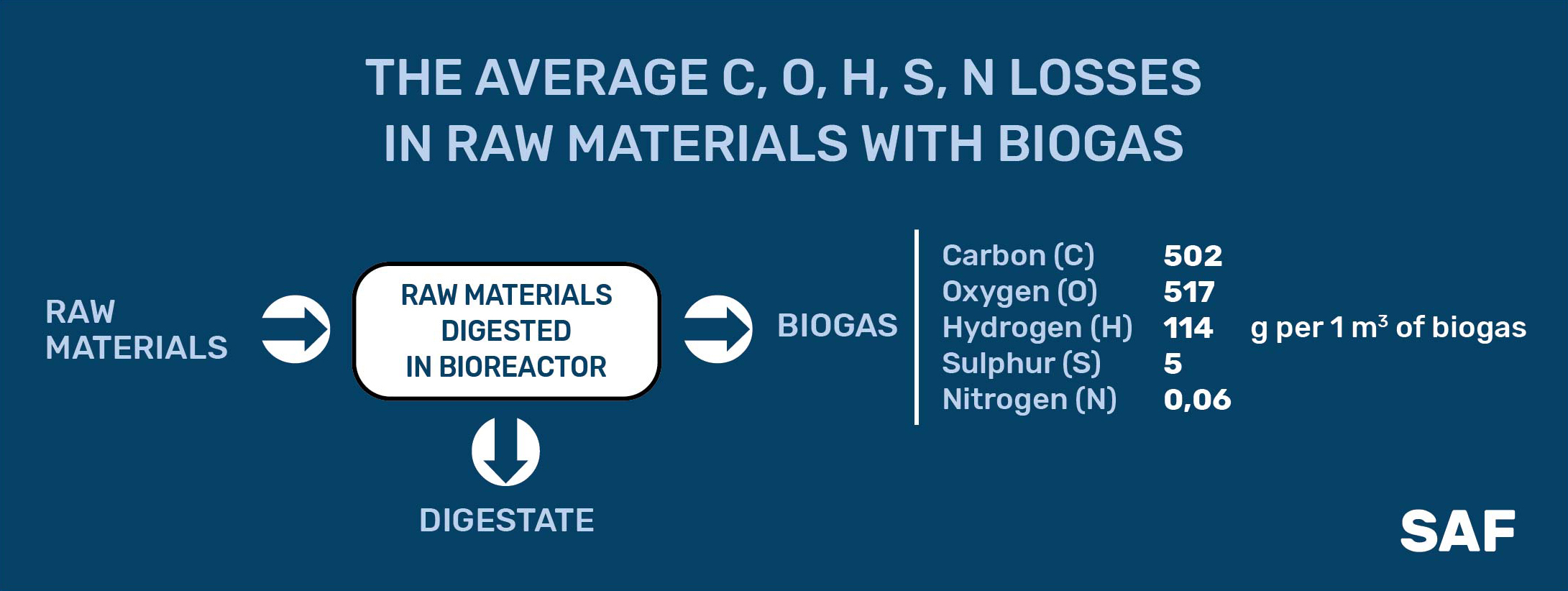

In the process of methane fermentation, part of the organic matter is transformed into biogas with the reduction of carbon (C), hydrogen (H), oxygen (O), sulfur (S) and nitrogen (N) in the feedstock. With each one cubic meter of biogas the input raw material loses are an average of 502 g of C, 114 g of H, 517 g of O, 5 g of S and only 0.06 g of N (Fig. 2).

Figure 2 – The average C, O, H, S, N losses in raw materials with biogas

Much of the sulfur can be returned to the digestate if hydrogen sulfide treatment is done in the bioreactor. If biogas desulfurization takes place in a separate item, the efficiency of hydrogen sulfide removal is much higher, and the resulting sulfur-containing product (solid or liquid) can be a marketable product, for example, for the production of complex mineral or organic-mineral fertilizers.

All other input macro- and trace elements are present in the digestate. Therefore, the digestate chemical composition is mainly determined by a mixture of components entering the bioreactor including raw materials for biogas production and various additives (enzymes, micro-nutrients, reagents, water, etc.).

Thus, the digestate has the following important for soils and agricultural production characteristics:

- Complex of macro- and micronutrients (N, P, K, S, Co, Mo, Zn, Fe, Mn and others) necessary for plant growth.

- The high content of readily available nitrogen for plants (60-80% of the total nitrogen content).

- Balanced C/N ratio (20-30).

- pH value close to neutral (6.5-8.0).

- It does not contain (minimal content) viable weed seeds and pathogenic microflora (subject to the required process duration and temperature).

[1] Adapted from: Torben Ravn Pedersen. Digestate as fertilizer – recycling of nutrients. The environmental impact and the value as a fertilizer / Nordic Biogas Conference, 2016

Author: Petro Kucheruk – expert of Bioenergy Association of Ukraine

Read also:

Organic fertilizers in agriculture nutritions recycling

Consumption of organic fertilizers in Ukraine

The types of organic fertilizer produced in Ukraine and its market niches