The cost of commercial biomethane has three main components, namely: a) the cost of biogas; b) the cost of enrichment of biogas to biomethane; c) the cost of logistics of produced biomethane.

The biomethane project differs from the producing electricity and heat from biogas project. Instead of the cogeneration unit for the “raw” biogas, a purification plant will operate, whereby the physical and chemical parameters of such biogas will be given to the required GHG supply, or for refueling transport. The result is enriched biogas, which is commonly called biomethane.

In the EU countries, the physical and chemical parameters of biomethane, depending on the direction of its use, are regulated by relevant national standards, such as the German biomethane standard supplied in the natural gas (NG) network DVGW G260/G261, the European standard EN 16726: 2015, and from May 2017 year – also the European unified standards for biomethane EN 16723-1 (for NG networks) and EN 16723-2 (for transport). In Ukraine, biogas producers may submit it to the gas transportation system (GTS) if at the place of biogas transfer to the GTS its physical and technical characteristics will meet the standards for natural gas, as defined by the GTS Code.

The required degree of biogas purification will, on the one hand, depend on the quality of “raw” biogas, and on the other – from the requirements of the standard. This will determine the choice of the appropriate cleaning technology and the cost price of commercial biomethane.

Today there are 4 basic technologies for biogas upgrading to biomethane: membrane separation, absorption (water, chemical, physical), adsorption under variable pressure (PSA) and cryogenic purification. In this case, the cost of production of biomethane depends more on the capacity of the treatment plant and less on the type of technology.

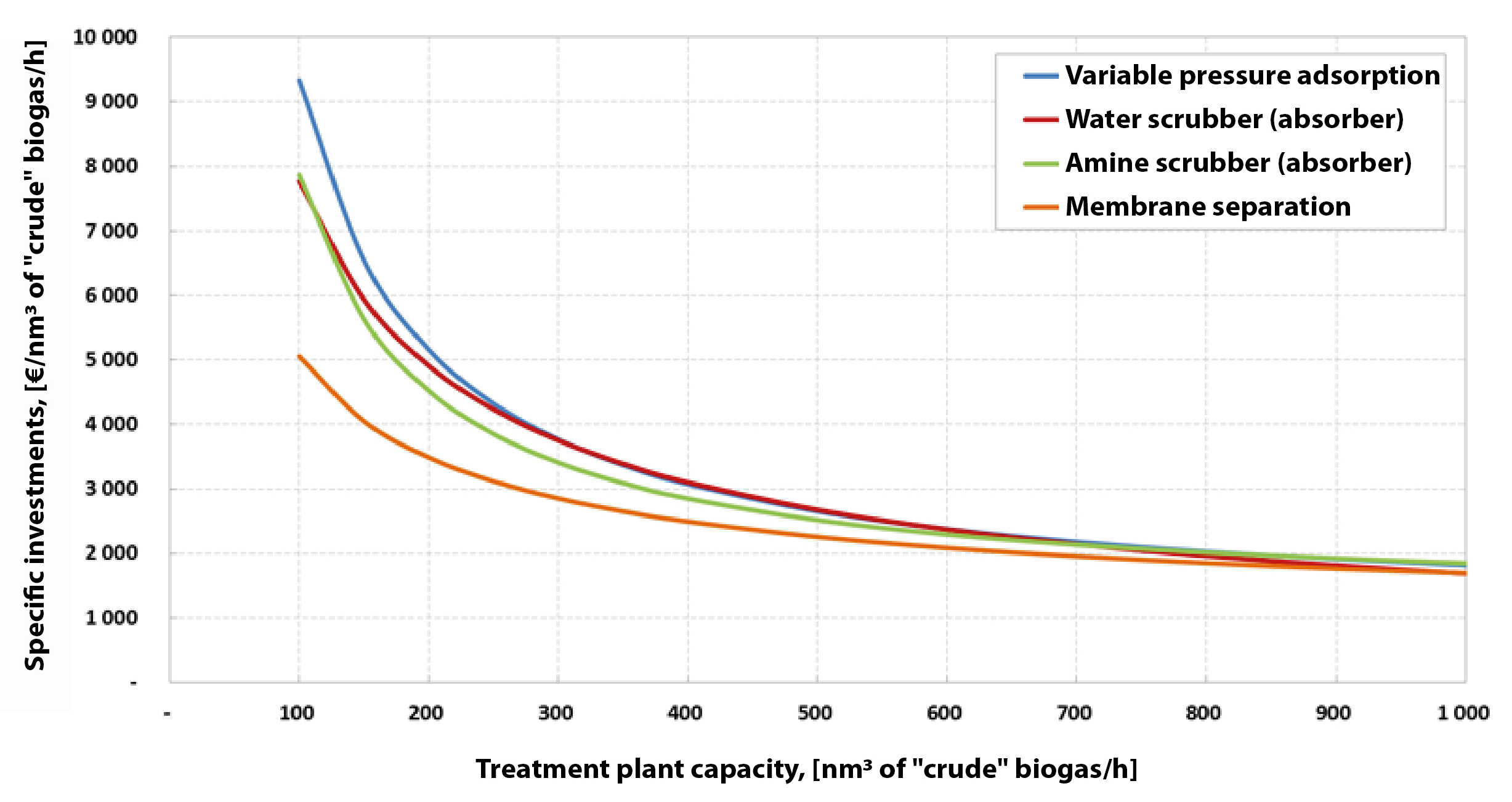

Fig. 1 – Specific investments for the enrichment of biogas to biomethane (1)

As can be seen from Fig. 1, the specific investment costs are closely correlated with each other over a wide range of capacities for the three common types of technology, namely PSA, water absorption and amine absorption. At small purification capacities, membrane separation differs favorably, and when the “crude” biogas purification capacity is increased to 900-1000 nm³/h the difference between the cost of different technologies is practically leveled and amounts to 1700…1850 €/(nm³/h), which is 0.9-1.2 times different from investment in cogeneration plant of appropriate capacity. Thus, the investments in the biomethane plant and the conventional biogas plant with combined production of electricity/heat from biogas are commensurate.

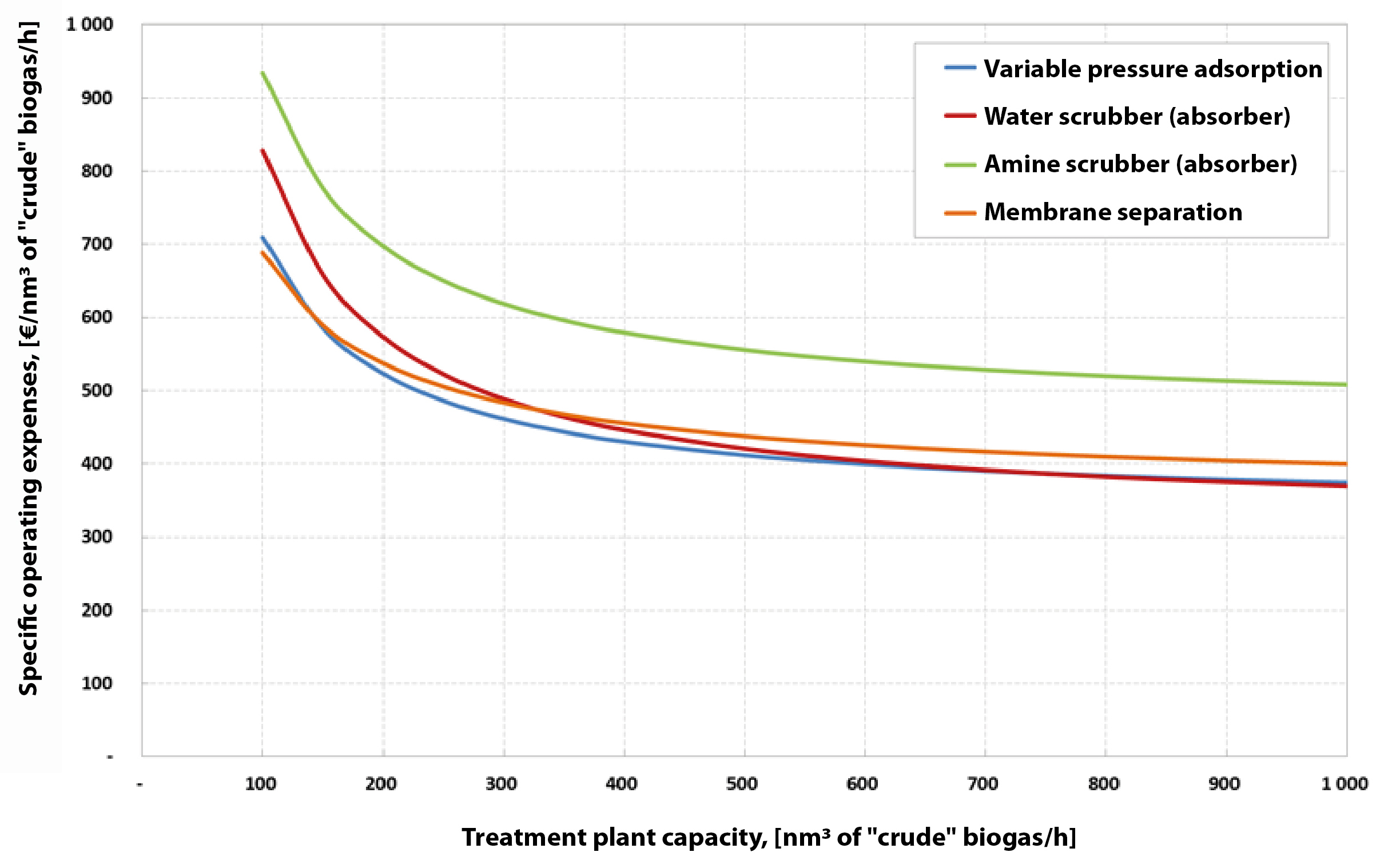

At operating costs, the absorption of amines will cost significantly more, other technologies are quite well correlated with this indicator in a wide range of capacities (Fig. 2). With biogas enrichment with PSA technology, the cost of producing 1 nm³ of biomethane, depending on the purification capacity, will be from 7.6 to 14.4 euro cents, when using a water scrubber – from 7.5 to 16.8 euro cents, amine scrubber – from 10.3 to 19.0 euro cents, and from 8.1 to 14.0 euro cents – at membrane separation.

Fig. 2 – Specific operating expenses for the enrichment of biogas to biomethane (1)

The final cost of commercial biomethane will also affect the cost of compression to the required pressure, odorization, quality monitoring, calorific value adjustment, as well as the cost of logistics.

The total cost of commercial biomethane, taking into account the type of raw material for biogas production, plant capacity and logistics cost to the end consumer, can be 340-570 €/1000 m³.

Author: Petro Kucheruk

(1) Novakovits, P & Doczekal, C (2016) “Biomethane tool for economic analysis of biogas production, gas upgrading and utilization of biomethane”