Deviations of quality of biofuel from agrobiomass and technical characteristics of the equipment for its use from a settlement, and also unsatisfactory operating modes of installations do not always allow to adhere to the established ecological requirements. In particular, the environmental characteristics of the equipment used in some countries do not allow its use in other countries without ensuring state or local environmental regulations.

The main pollutants in the process of energy use of biomass, to which special attention should be paid, are:

- nitrogen oxides (NOx),

- carbon monoxide (CO),

- sulfur oxides (SOx),

- chlorine compounds,

- solid particles.

Operation of facilities from which emissions of pollutants exceed the maximum allowable limits is prohibited. And legal entities and individuals are subject to administrative liability for violations of the law and must pay a fee for pollutant emissions and pay additional fines for exceeding the permitted emissions.

Therefore, there is a need to apply methods to reduce pollutants in combustion products in order to provide technical environmental requirements, which are basically divided into two groups:

- Primary methods (organizational, preparatory, and regime measures aimed at fuel preparation and organization of the combustion process in the combustion chamber, including design solutions for boilers).

- Secondary methods (measures to reduce the concentration of pollutants in flue gases, through the use of specialized gas cleaning equipment).

Nitrogen oxides (NOx) are formed mainly by oxidation of nitrogen-containing compounds in the fuel and by oxidation of atmospheric nitrogen at high temperatures in the boiler furnace. To reduce them, first of all, primary methods are used. They involve proper fuel preparation, reducing the temperature in the combustion chamber, optimizing the excess air ratio, recirculation of combustion products, water injection, and multi-stage air supply, the latter being the most common.

For powerful plants that burn fuels with significant emissions of nitrogen oxides, secondary methods can be used. They include measures of chemical purification of flue gases, namely oxidation of nitrogen oxides with subsequent absorption of received products, restoration through using catalysts, and absorption by special sorbents. Among these measures, the most promising are recovery methods.

The presence of carbon oxides (CO) in the combustion products indicates incomplete combustion of fuel in the furnace of the boiler. Reduction of emissions of carbon oxides, as well as other products of chemical combustion of biomass (soot, hydrocarbon compounds), can also be carried out by primary methods, which usually involve optimizing the design of the furnace and combustion regime.

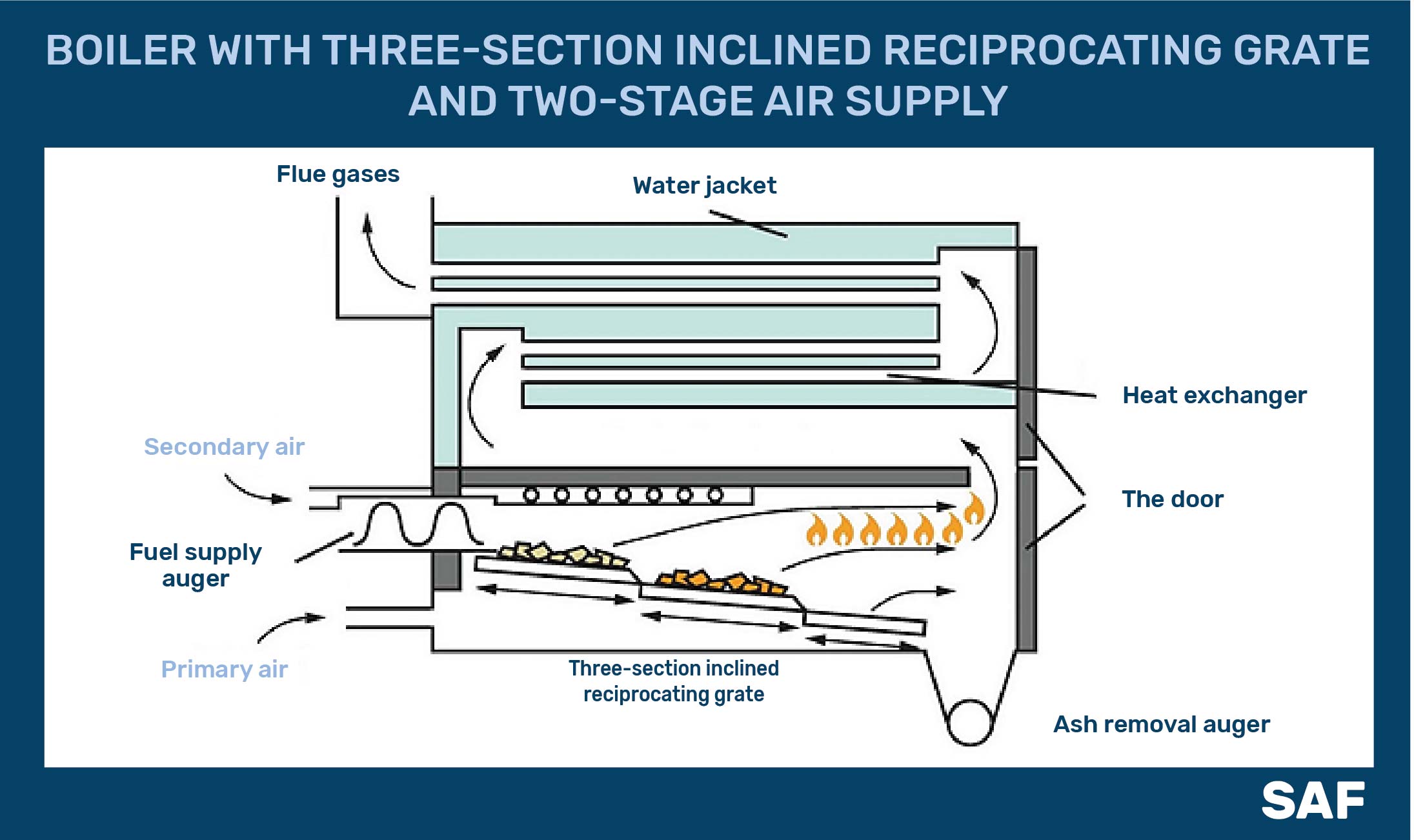

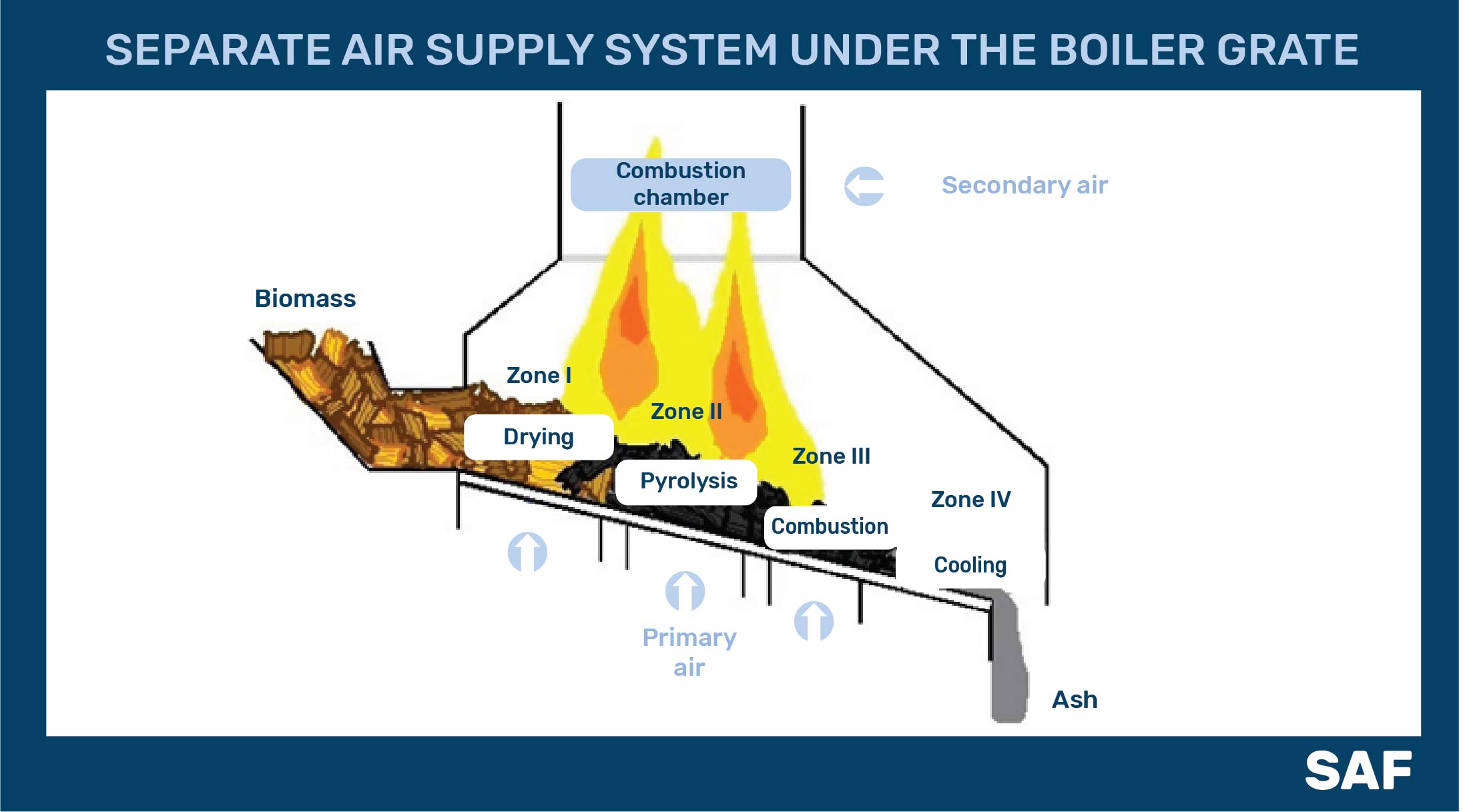

Separation of the blast airflow into primary and secondary with its subsequent supply to the fuel combustion zone, regulation of air quantity, optimization of grate size and methods of fuel supply, grinding, pre-drying to 15-20% humidity, and prevention of furnace overload – all this allows reduce emissions of chemical waste products of biomass. In particular, the correct adjustment of the air supply with its distribution along the grid in accordance with the fuel distribution can significantly improve combustion and reduce emissions of carbon monoxide (CO) in boilers.

The presence of sulfur oxides and chloride compounds in the combustion products depends exclusively on the value of sulfur and chlorine content in the biomass. In particular, the increased chlorine content is characteristic of straw, which absorbs it from the soil. During the process of burning straw (in the presence of intermediate products of combustion and gasification of chloride compounds) dioxins can be formed, as well as toxic phosgenes (COCl2) and hydrogen chloride compounds (HCl). The significant chemical activity of chlorine and its ability to attach to unsaturated compounds such as carbon monoxide (CO) is the basic reason.

The removal of solid particles from the combustion products is associated with the presence of volatile ash, which is part of the ash residue in a suspended state. This type of ash settles on the heating surfaces of the boiler, accumulates in the ash hoppers, and partially enters the combustion products in the form of solid particles emitted into the atmosphere.

The content of solid particles in the combustion products significantly depends on the type of fuel, its ash content, and biomass combustion technology. For example, the lowest uncontrolled particulate emissions at 70 mg / m3 are observed during gasification of solid biomass, while for direct biomass combustion technologies they can range from 300 to 540 mg / m3.

To clean the combustion products from solid particles, secondary methods are used, which involve the use of gas cleaning systems, such as:

- cyclones and multicyclones,

- scrubbers,

- bag filters,

- electrostatic precipitators.

The choice of their type and characteristics is a responsible engineering measure, which is based on the mass flow of flue gases (m3 / h) and the initial and final concentration of solid particles (mg / m3), which must meet the maximum allowable emissions of pollutants into the atmosphere. In particular, for agrobiomass boilers it is recommended to use a two-stage cleaning system based on cyclones and bag filters, or electrostatic precipitators, depending on the capacity of the installation.

Measures and flue gas cleaning systems increase the cost of both the boiler and the boiler house as a whole. The cost of boilers is set mainly by the manufacturer depending on the design features, used materials, and equipment. The cost of the boiler also includes measures to reduce emissions of pollutants into the atmosphere. Therefore, as a rule, more expensive boilers have better environmental indicators.

According to the materials: Practical guide to the use of biomass in the municipal sector of Ukraine (for representatives of government agencies and public organizations that working in the field of ecology) / G. Geletukha, Y. Matveev, E. Oliinyk, D. Kutsyi. UN Development Program. Kyiv, 2017. 54 pp .: https://bit.ly/3iHXFcL.