During harvesting, sunflower by-products can have a high moisture content, making it difficult to store and process them into solid biofuels. At the same time, such wet biomass can be used for biogas production. However, due to the high content of lignocellulosic chemical compounds in sunflower by-products, it must be pretreated for mechanical, physical, or chemical destruction before the fermentation.

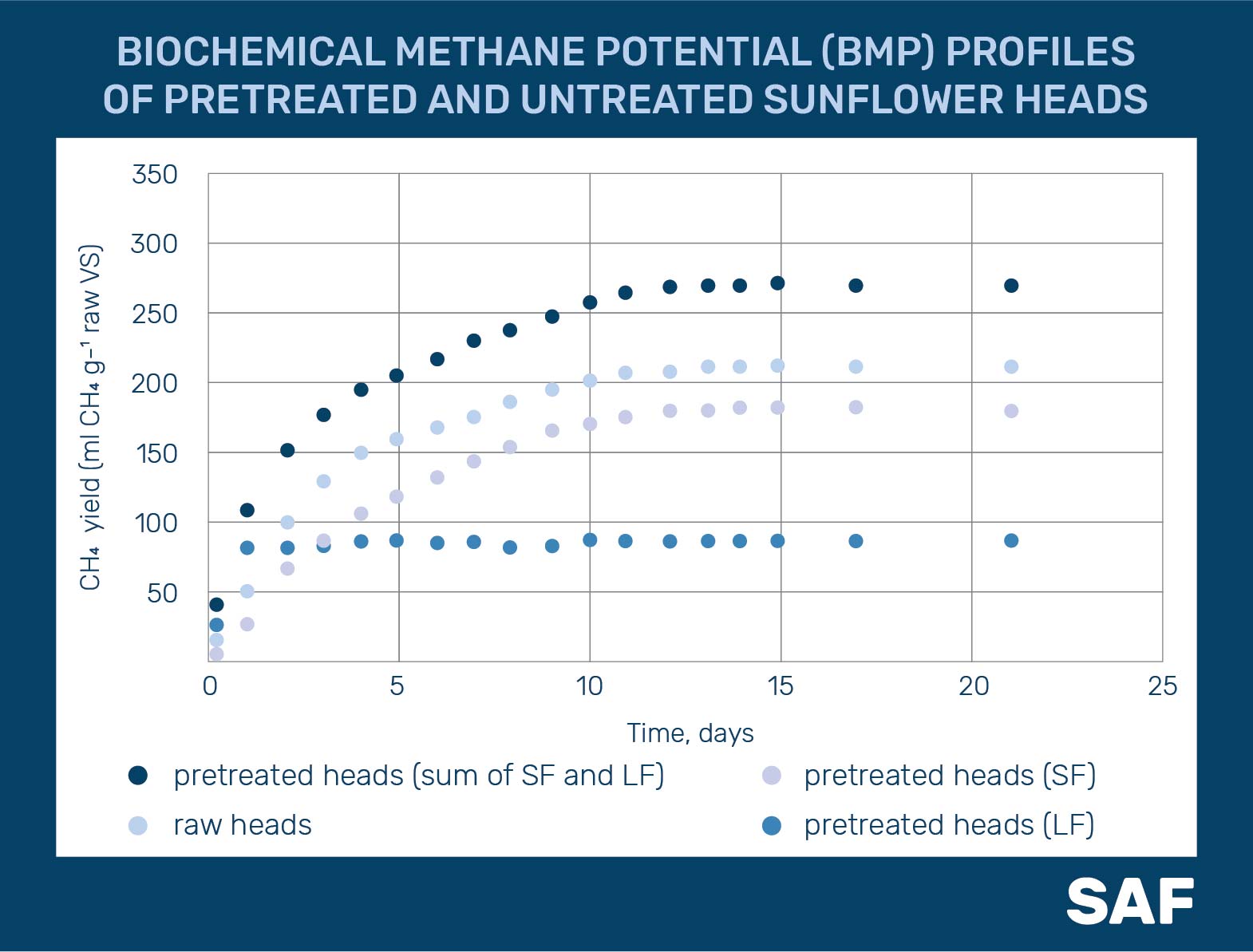

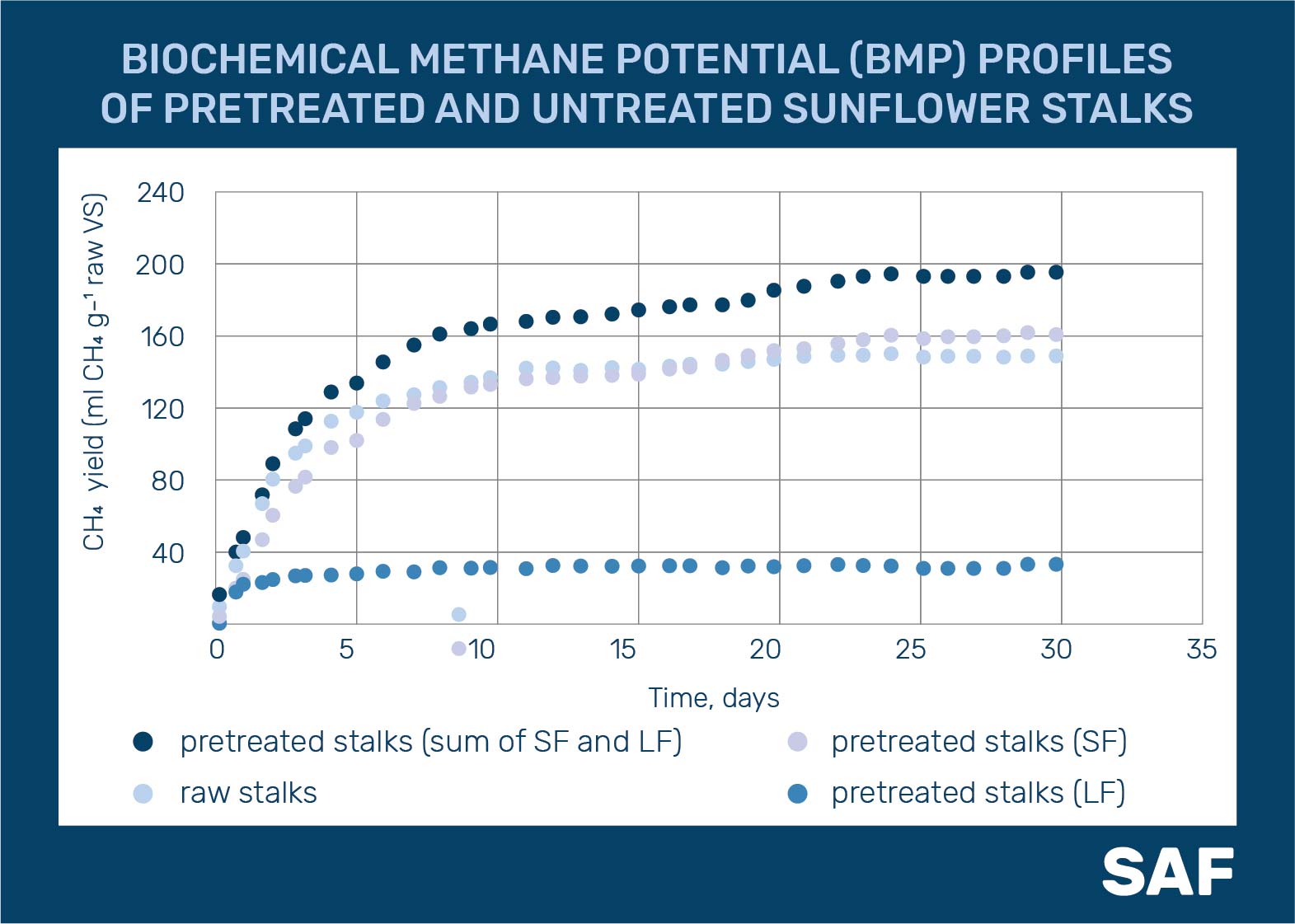

Methane yield from sunflower heads and stalks is shown in the figure below The biochemical potential of methane of untreated heads was 210 ± 1.97 ml of CH4/g volatile solids (VS), and 127.98 ± 5.19 ml CH4/g VS for untreated stalks.

Notes: Values correspond to three times repeatability of independent values ± standard deviations (error bars). SF: solid fraction, LF: liquid fraction.

Heads are considered to be a better raw material for biogas production in comparison with sunflower stalks. After alkali pre-treatment, the yield of methane from the head residues was 268.35 ± 0.11 ml of CH4/g VS, while the yield of methane from the treated sunflower stalks was 168.17 ± 6.87 ml of CH4/g VS [1]. According to the experimental data, the content of VS was 79.9 ± 0.5% of dry weight in heads and 87.7 ± 0.1% of dry weight in sunflower stalks. Thus, up to 214 m3 of methane can be obtained from 1 t d.m. of heads and up to 154 m3 from 1 t d.m. of sunflower stalks.

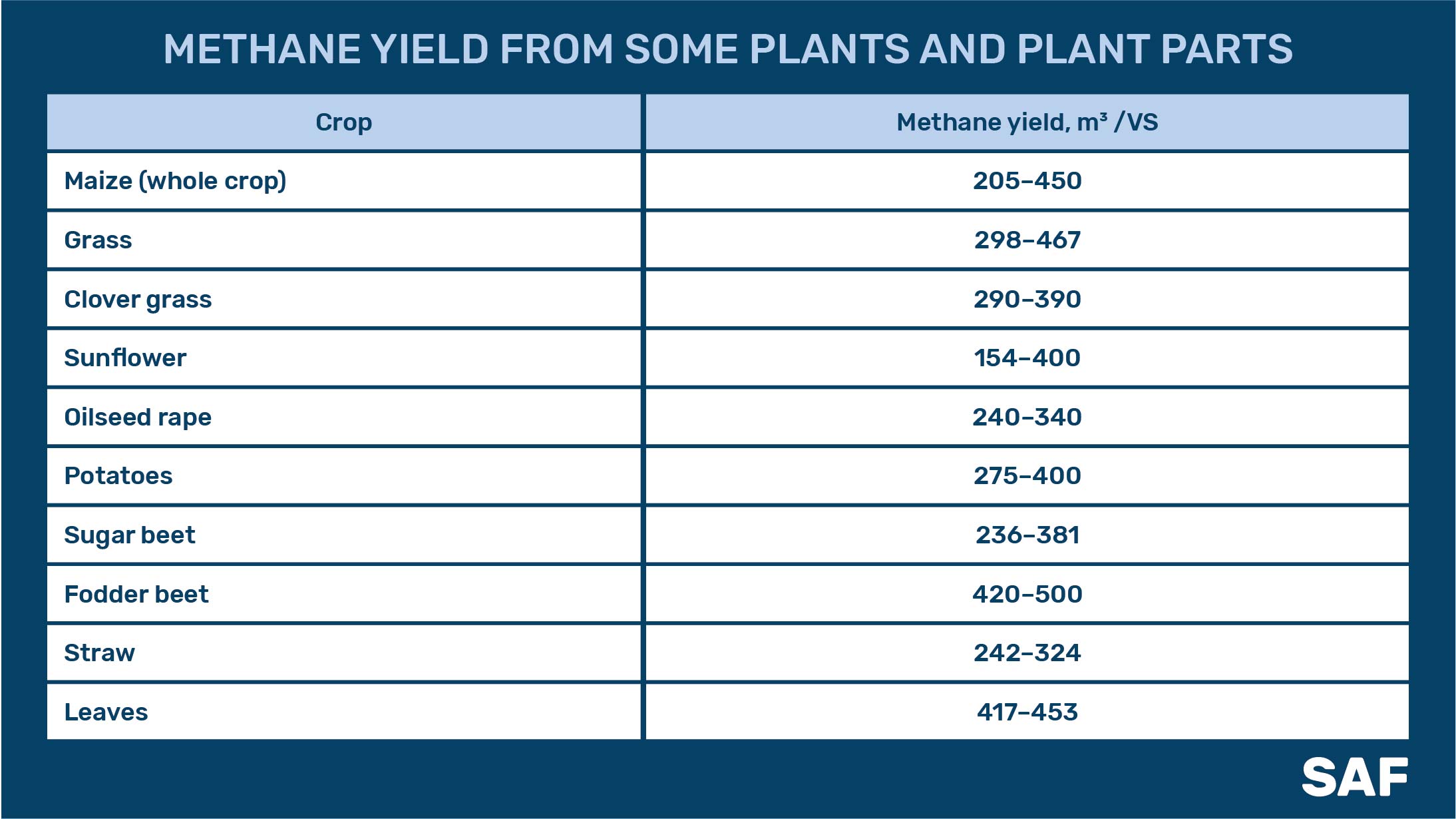

Some farmers grow sunflower for green fodder and silage. For comparison: the yield of methane from sunflower silage is 298 nm3/t[2]. The yield of methane from various plant substrates is presented in the table.

The analysis of different options for the pre-treatment of sunflower stalks before the anaerobic fermentation was performed in the studies[3], [4]. The highest yield of methane (259 ± 6 ml CH4/g VS) was achieved after alkali pre-treatment of stalks with 4% NaOH at a temperature of 55 °C for 24 hours.

Thus, alkali pretreatment of sunflower by-products before the anaerobic fermentation, as well as alkali pre-treatment of other lignocellulosic substrates, increases methane yield, but to ensure the high process efficiency, more concentrated substrates (over 35 g d.m./l) and heat recovery systems must be used.

The material is prepared on the basis of theoretical research and experimental research by UABIO experts.

More professional information about this question is presented in the analytical note UABIO “Prospects of sunflower residues use for energy”: https://uabio.org/en/materials/8875/.

[1] Marinela Zhurka, Apostolos Spyridonidis, Ioanna A. Vasiliadou and Katerina Stamatelatou Biogas Production from Sunflower Head and Stalk Residues: Effect of Alkaline Pretreatment / Molecules 2020 Jan; 25(1): 164.

[2] Guide to biogas. From production to us, FNR, 2012. https://mediathek.fnr.de/media/downloadable/files/samples/g/u/guide_biogas_engl_2012.pdf.

[3] F. Monlau, A. Barakat, J.P. Steyer, H. Carrere Comparison of seven types of thermo-chemical pretreatments on the structural features and anaerobic digestion of sunflower stalks, Bioresource Technology 120 (2012) 241–247.

[4] F. Monlau, P. Kaparaju, E. Trably, J.P. Steyer, H. Carrere Alkaline pretreatment to enhance one-stage CH4 and two-stage H2/CH4 production from sunflower stalks: Mass, energy and economical balances, Chemical Engineering Journal 260 (2015) 377–385.