The corn stover harvesting technology differs from cereal straw harvesting by the additional operation of windrowing with a stalk-shredding windrower. A three-pass system is used: combine harvester + tractor with stalk-shredding windrower + tractor with a baler for large square bales.

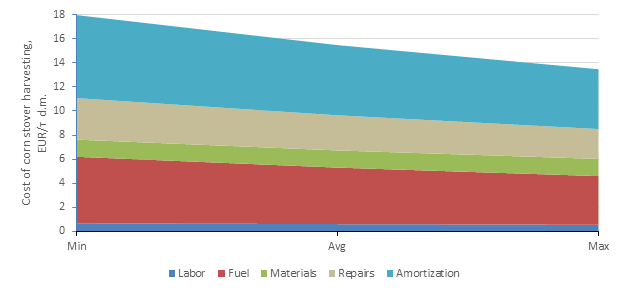

Initial conditions: the duration of harvesting is 25 days, the duration of work is 10 hours/day, deductions for maintenance and repair is 5%, amortization is 10 years, the salary of the operator is 17.7 euros/day. In the following calculations, we consider three scenarios of the biomass harvesting: minimum – harvesting of 2.5 t d.m./ha; average – harvesting of 3.5 t d.m./ha; maximum – harvesting of 5.0 t d.m./ha. The large square bales are transported by a truck with a semitrailer to a storage facility at a distance of up to 10 km.

The results of the estimation of the net cost of the harvesting of corn stover for the three volumes of biomass collection per unit area are shown in Figure below.

Cost of corn stove harvesting by the three-pass system

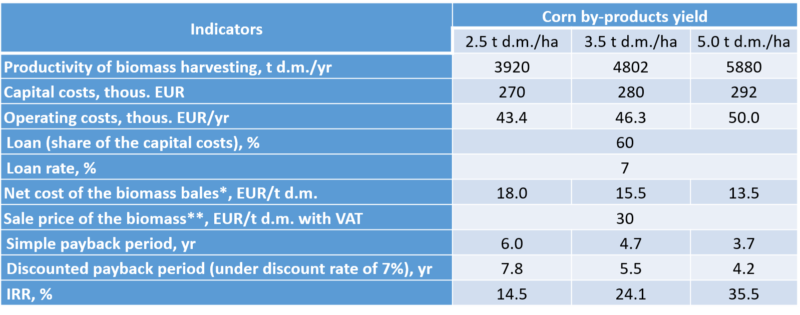

The results of the feasibility study of the corn stover supply chain based on the three-pass system are given in Table. 3.5. Thus, when corn stover harvesting in the amount of 5.0 t d.m./ha, the simple payback period of the harvesting unit is 4.2 years. In the scenario of harvesting average biomass volumes of 3.5 t d.m., which can be achieved with a corn yield of 75 m.c./ha, the simple payback period of such a harvesting unit is 5.5 years. At the yield of corn stover is 2.5 t d.m./ha, the simple payback period of the harvesting is 7.8 years.

Techno-economic assessment of corn stover harvesting by the three-pass system

* The cost includes direct costs of harvesting biomass and deductions for equipment amortization.

** The price is equal to the sale price of corn stover (W25%) of 25 EUR/t without VAT.